|

|

Forum Index : Windmills : Need some feedback on tower.

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

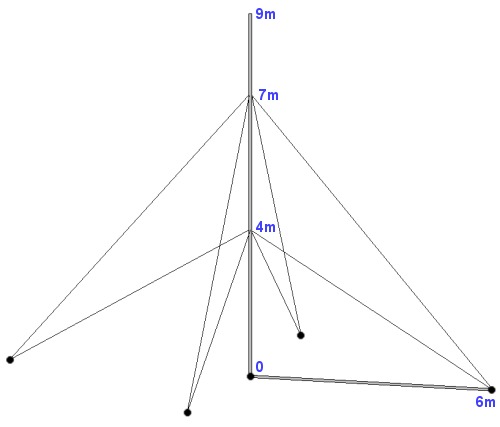

I'm planning to put up a windmill tower on my new block of land in the next few weeks. Its going to be a few months before I can build a shed on the new block, but I found out recently the bare block of land next door will be up for sale soon. So I want to get a tower up with a tied off windmill, so the new neighbours know what they are getting into before buying. If they buy and I put up a tower later, they may complain. This is what I'm planning.

The tower will be 9 meters high. top guy wires join at 7 meters, meaning I can run a turbine up to 4m diameter, though closer to 3.5m in reality. Another set of guy wires join at 4 meters. 8 guy wires in total. I'll be using a gin pole to raise and lower. Guy wires anchored 6 meters out from tower base. For the tower I'm looking at 65mm nominal bore medium thickness gal pipe ( OD 76.1mm ). For the gin pole I'm thinking either 40mm medium or 50mm light gal pipe. When in use I'll attach additional guy wires on the gin pole to stop it bending. I'm not sure about a suitable guy wire size? Does 6mm sound OK, gal wire over a steel center. Any feedback welcome. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glenn Looks good should be very strong, the 6 mm wire has a BS of around 3 tonnes and with a 6 to 7 M ratio it should never move. 50mm RHS would be a better call on the gin pole as it is more rigid than pipe. All depending on the weight of the turbine of course. 3 or 4 strands of fencing wire spun into a cable would make a cheaper option unless you have a good source of cable. All the best Bob Foolin Around |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Hi Glenn, I can only speak from my ham radio antenna mast experiences but it was with a home built 12m telescopic lattice mast (square section) and it was guyed with 6mm gal wire rope. I had the thimbles swaged in - on my 6 ton car jack press in home made dies - and these never gave way. If you use the U bolt type wire clamps use 3 at each end. I also used turn buckles for final tensioning and a short section of chain & shackle for coarse set up of the pre made stays. Regarding your gin pole arrangement, you have to make sure the guy wires at right angles to the gin pole remain tight throughout the raising process. That is not always easy if the ground slopes and you get uneven guy lengths. For this reason I used a seesaw raising/lowering method after my mast was telescoped down. I had a full size 3 band cubical quad antenna up there which had a fair bit of wind resistance but my upper guying attachment was closer to the top. If this was my mast I'd fit 3 diamond stays to the top section to keep it straight, these need only short (0.3m?) spreaders and would not rob much blade clearances if the spreaders are at the 7m level. Perhaps you can even find some cheap (or free) lattice mast sections ex 2 way radio masts which got superfluous when the mobile phone took over. These would, IMO, be far stiffer for the same weight than your thick wall pipe. Good luck with your build. Klaus |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

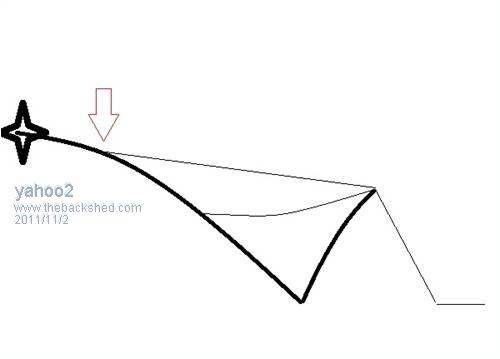

I have had a glance at my steel spec book, i assume you are not looking at dodgy old pipe but what is called CHS (circular hollow section) so CHS grade 250L0 76.1 od medium will be a 3.6 mm wall thickness. the max serviceable load on a 7 metre span would be 670 newtons. for comparison in the same grade 88.9mm X 4mm is 1210 N and 101.6 mm X 4mm is 1830 N. There is only one point that the poles will be loaded, I have tried to draw it but its no masterpiece, if it bounces or a u-clamp slips then grips while the tower is lowering the flex will whip the poles.

The tube is 6.5 metres standard length if you leave some extra lowering room, and move your guy blocks a fraction wider you would have an upgrade path to 13 metres, I have had a look at the weight of a few commercial 4 metre diameter blade turbines, 3 inch may be borderline for that yahoo re-edit ( the point between the arrow and the ground is the 7 metre span that is loaded) I'm confused, no wait... maybe I'm not... |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Now that I look at my own drawing its a 9 metre span with an load offset from center, I cant do the formula for that, here is the centered loads. --------max service load----load to bending (damage) 76.1 X 3.6 mm 410 Newton-----3790 N 76.1 X 5.9 mm 612 N----------5830 N 88.9 X 4.0 mm 731 N----------5770 N 101.6 X 4.0 mm 1110 N--------7620 N If gravity is causing the load its roughly 10 newtons to the KG the reason that Bob is suggesting square hollow section as a stronger alternative for a gin pole is that it is made with thicker wall options and from the higher 350 or 450 grade steel, Australian mills dont roll circular hollow in 450 and 450+  I'm confused, no wait... maybe I'm not... |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Glenn, If you want to save on cost and not compromise the strength of the tower,you can use 4mm cable for the lower guys.The load is carried on the upper guys while the lower ones hold the mast straight.You might consider it to much bother for the difference in price all the same!I don't know if laws are consistant across Aus,but I've been informed that towers up to 15mt in my location,rural south west Vic. don't need a building permit or shire aproval.This advise came directly from the engineer.I'm going 19mt so,still in the planning stages.Cheers Rastus see Rastus graduate advise generously |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

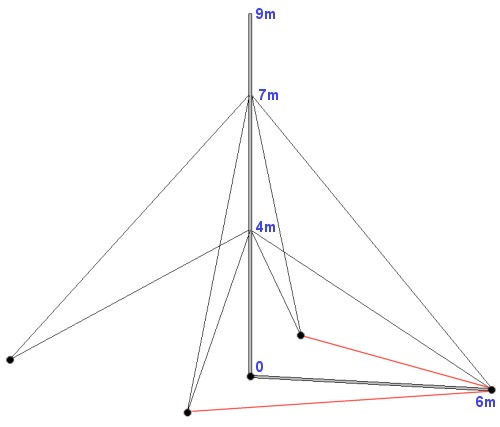

Glenn, further to my comments above,can you add to your drawing guy wires from the tip of the gin pole (marked "6m") to each of the ground anchors at right angles of the gin pole heel attachment? This might help those who do this for the first time and follow your drawing. These extra guys are *essential* during the lifting/lowering process to keep the gin pole aligned. I found out the hard way what happens if these are omitted  Klaus |

||||

| Air Bender Senior Member Joined: 25/01/2011 Location: AustraliaPosts: 206 |

Hi Glenn, I just set up a pivoting pole that pivots at 1/3 of the way up the pole the pole that it pivots on I concreated 1.5m into the ground the main pole is 1 inch gal pipe and the pole that it is hinged to is 1 inch square gal tube and I have a chain conected to the base of each pole to prevent the mill from hitting the ground when It pivots down. When Im not at work I will post a picture of the set up on my build post. My pole is not quite as long as what you plan to put up, and my mill is probably a fair bit lighter but if I was going to put up a heavier mill I would use the same set up but add a spreader at the pivot point and add a half diamond from the where the top guy wires connect down to the spreader and down to the botton of the pole so the spreader faces upwards when the pole is pivoted over. I pivoted the mill up and down by hand the other day in gusty winds without any effort, the pole was a bit bendy but nothing to worry about. I have not put any inner guy wires in the bottom as when the pole is raised I clamp the bottom of the pole to the base of the pole that is concreted in the ground giving me extra suport in the bottom 1/3 of the pole. I only have 3 guy wires on this pole, I have a small back yard and space is limited which is another reason I dont have a pole pivoting up and down at the base. Hi Rastus I wonder if that law includes a back yard in a small rural town in south west VIC, I could always tell them that Rastus said it was Ok.

All the best Dean |

||||

| Rastus Guru Joined: 29/10/2010 Location: AustraliaPosts: 301 |

Hi Dean, You could try that for a laugh!I started a thread a while back about red tape,but havn't kept it up todate.One of the problem regulations you could encounter is the tower/mast needs a fall area within the boundary fenceline that doesn't pose a damage risk to buildings/property.My closest neighbour lives kmts away,he can object because he owns pasture/land over the road,even though I'm the only one with buildings that need to be free of risk.It's not all plain sailing!If I erect a mast or tower up to 15mt high I don't need planning aproval or a building permit.Yes that would be the easy way out,but it doesn't satisfy my preferences.So more prep is required.Cheers Rastus see Rastus graduate advise generously |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thanks for the great information guys, especially the loading details and the wire strength. Yes I should have included the gin pole side guy wires in the pictures. Here's the pic with the gin pole guy wires shown in red.

My last tower was a pivot tower Dean, very easy to use. This time I want to try a gin pole lifted tower, mostly becasue I've never used one before. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

I am not sure that metal loading specs help a great deal, I cant do an accurate calculation because it is such a complex load. My gut feeling is that it should do 140 KG with some margin, but it wont look pretty.The height that the gin pole guy wire attaches makes a huge difference. Most of the failures I have seen are related to the quality of the build not the materials. Guy loops welded straight to the pole with no load spreader, base hinges that jam, seize or just collapse. In the past I have cut the top out of a 205 litre drum, filled it with water and hooked it to the tower apex, you get it about 30 cm off the ground and bounce it around a bit, if I was happy with that I bolted a 100 Kg weight to the pole and lifted the tower. I'm confused, no wait... maybe I'm not... |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi Glenn, I have never tried to stand a mast as you plan to do, but I have had some experience at standing moderately tall poles. For this I used an A frame, which I assume that you would rig and lift in much the same way as a gin pole. Yes, it does mean that you need effectively two gin poles, but the set up during lifting is inherently much more stable, so long as the A frame feet are well anchored (read set in a hole). Regards Don B |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Glenn,,, Why not just set a permanent vertical "gin type" pole . You have seen mine ,it's been up for 5 years now and never needs taking down . Also backs up as additional guying for the raised pole. I installed pole steps on mine ,so I can climb (7 mtrs) and grease the pulley blocks that carry the lifting cables. Another advantage with this set-up ,, your side anchor points need not be exactly the same height and distance and in line with the pivot (base).. We just detach one side and Ilda ( resident all-rounder) holds the guy wire ,taking any slack or releasing the tension , as the main mast is lowered. all very easy and no swearing.. We can lower our 57 foot tower in approx 5 minutes . I've even done it by myself a couple times (but she keeps an eye on me from the kitchen and wanders out to lend a hand most times.) Mine lowers onto concreted "Y" supports about 2 mtrs tall , so working on the mast is very easy. My electric heavy duty winch has remote control with the rope folds going through 2 and 3 sheave pulley blocks . I can wander around out of the fall area observing all guys and making sure everything is going fine ,especially on the raising operation . Chain "starters" around 1 mtr at the base of all guys is wise ,,as these take up any twist or kinks in the guys and importantly are great for fine adjustment. I wish you success whichever way you go .Remember at all times "Safety First" Bruce. Bushboy |

||||

| Perry Senior Member Joined: 19/11/2009 Location: Posts: 190 |

Hi Glenn, I think your setup as drawn above should be OK. The comment on using the 4 mm rope for the lower guy's is a good one as well. Haven't run any numbers an this is shooting from the hip but I would be concerned about the 2 meters of unsupported tower at the very top. If you consider the rest of the tower rigid up to the top guys it's like having a non supported tower that sticks 2 meters out of the ground. For the relatively small diameter proposed for your tower I am not sure it will hold. IF this tower fails, I would guess it would buckle just above where the top guys anchor. Maybe you could double it up with a sleeve or something. Just to consider, Perry |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Perry , I'd reckon the 2 Mtrs above the top set of guys is for the mill and blades -. He or anyone has no option but to leave this amount of free standing mast .. Bye the way ,,, My top 20 feet or so of mast bends a fair bit when lowering , was worried about that ,but so far she's been up and down many times and still straight as a die.( I have two lifting guys equalising their pull(load) through a single sheave pulley ,so maybe when the load comes off one point it then transferrs to the more demanding point..hard to explain. My new Exmork weighs in at around 60 Kg including the 112mm heavy duty 2 Mtr stub mount., so thats a fair bit to raise and lower. Have a good weekend ,everyone. Bruce. Bushboy |

||||

| birdhouse Regular Member Joined: 27/01/2009 Location: United StatesPosts: 63 |

glenn- been a while since i posted here. congrats on the land purchase!! feel good uh? i'm in the us, so the meters thing takes some converting. i think the pipe size your talking about is pretty skimpy, especially for the top un-supported stub with a ~17' machine hanging on it. i also find it odd the height you've chosen. is the pipe free, or is ~15' lengths standard over there? i know it can be calced out by engineers, but hey, many things calced by engineers have failed through the ages. if it were me, and i was going to put the time money and energy into it, i'd go for a 40' tower made from two 20' pieces of 4" pipe. use the thicker pipe almost all the way to the top, them weld a reduced stub at the end to hold the machine. this would give you a ~13m tower with the same amount of guys (though slightly longer). and to boot, it would be significantly stronger. another chunk of the same pipe could be your gin pole, and you'd be off to the races with a very sturdy tower. HERE is the story on my 70' tower build if you feel like checking it out. best of luck! adam i pee more than once before flushing, and don't have to flush at all up at the ranch! |

||||