|

|

Forum Index : Windmills : pics of the Lenz and build notes

| Author | Message | ||||

| thefinis Regular Member Joined: 23/08/2006 Location: United StatesPosts: 53 |

Okay I'll try and put everything in meteric. After reading about Ed's Lenz2 and seeing several others including Glenn's I decided to take the plunge and build this big wing. I have built several other vawts with varying success, none of which performed as well as a high speed hawt. I looked at many different materials wanting something common and hopefully cheap. I ended up with something that fit but in its current form is temporary. (1/2"x4'x8') 1.27 x 122 x 244 cm blue foam insulation board by Dow. It bends around to make my front curve half of a 76.2 cm (30")circle. I do not think I could have made it bend around any smaller curve. Broke the first one while trying to make it bend. It was supposed to fit perfectly with the it taking (8')244 cm to go around the curve and make the flat side of the wing. It didn't as the foam is 1.27 cm (1/2in)thick and the outside stretched so it ended up being several cm too long. My finished diameter of 76.2 needed an inside diameter of 73.66 and that was what the foam board saw. This big a wing I have had to add at least one cross brace and it may need more. It needs more screws and I added a piece on both ends of the foam to secure the ends. It has painted osb winglets and plywood half circles. I still don't have it worked out on the best way to mount it on a tower even in its short test form. Should I run a shaft up the middle to tie the tops to or would just angle braces from the middle work. I hate to spend too much time but would hate to have it throw these wings off. The test tower is 335.28 cm (11') with the turbine on top it will be 457.2 cm tall (15'). A tiltup tower is on the drawing board with a geared speed increaser of 6.5-1 (final drive off old JD combine) Here are some of the pics from building. frame work pieces

added this brace

Here are few of past wind spinners sailwing

vawtmman's wing design

barrels saved from an S rotor

Finis Texas born and bred |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Wow! Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| thefinis Regular Member Joined: 23/08/2006 Location: United StatesPosts: 53 |

LOL I feel like I am building an air plane wing. It is how to mount it that is worrying me as even during building it catchs a bunch of wind. I think that I have about $35 US in each wing and could double the height and only spend an additional $16-20 US. It needs UV protection. If the foam holds the screws(with washers) in a good wind I will price a treatment like carved foam blades. Lift a cold one this weekend for those of us not able to come visit. Finis Texas born and bred |

||||

| Highlander Senior Member Joined: 03/10/2006 Location: AustraliaPosts: 266 |

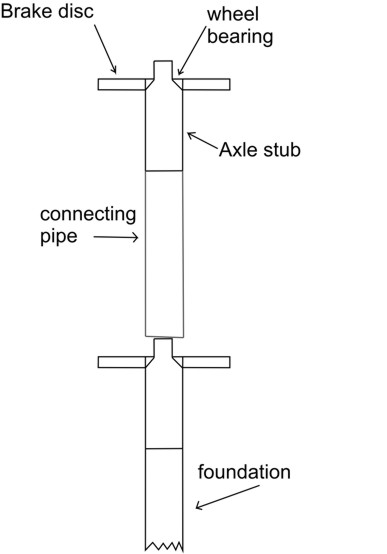

G'day thefinis, I've only been into this for 2 or 3 months. So if my ideas are a little crazy, don't be surprised. But I thought this could work. With cheap parts from a wrecker.

You could mount some bars from both brake discs to top and bottom of the wings. I like the balance weight on your tractor. Is that a drum you fill with water? I might try that, but I could always get my sister to sit on the front  Central Victorian highlands |

||||

| windstuffnow Newbie Joined: 30/06/2006 Location: United StatesPosts: 31 |

Wow finis, That's a big wing! It will be interesting to hear about the output of that beast when its up and running! Wrap a rope around the shaft and connect it to your tractor on a windy day and have a Tractor vs VAWT pull and see which one wins....

Have Fun!... looks like you are, didn't even have to say that... Windstuff Ed |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Finnis you Texans kill me you always have to build bigger for some reasons.Maybe its in your jeans.

The one thing i would be concerned with is the width of the blade on the upwind. How many blades are you planning? Has far has connecting the blades to a common shaft maybe welded steel spar? I know you just want to test your ideas im sure you can muster up a way.  Love these little faces Love these little faces

Nice work v |

||||

| Bug Bit Newbie Joined: 09/11/2006 Location: United StatesPosts: 2 |

WOW, that is big. My Lenz copy is 18"x18" wrapped with .02" thick plastic sheet. It seems everything must be rigid to work good. If it wobbles, it takes a lot of wind to start, but it is whisper quiet. Sorry, my metric is terrible so I didn't even try to convert anything.

Bug Bit |

||||

| thefinis Regular Member Joined: 23/08/2006 Location: United StatesPosts: 53 |

Highlander THat tank is a spray tank for chemicals but it can be used as a counterweight if pulling or using heavy plows. Your idea needs a little refinement. you need at least two bearings with some seperation hard mounted to the tower/support to handle the loads and usually a stub shaft to pull power from. I am having trouble with the brain and the eyes not seeing the same thing. My brain keeps saying this is no bigger than anything else I have put up and only half as high. It says you can only pull so much power from any rotor swept area with how much depending on how well you design it. My eyes keep saying look at the size of these wings and how much wind they will catch. I think that I have a spring scale big enough but I am afraid that the friction bushing is going to go up in smoke when I tighten it down to pull a brake hp reading. Three wings. All my models have been three wing after I built the two wing model and had the vibration problems. Bug Bit nice how much does it make or have you had a chance to measure the output? Ed has stressed that all of the measurement ratios and angles must be kept acruate for it to perform right. If it wobbles it will throw it out of the diameter path it is designed for. One of the things I am trying to avoid while wondering if it needs a center shaft up to the tops of the wings. I have looked at a pvc skin for mine but the thin version .06 inch has little structural strength/floppy and is almost 3x as exprensive as the foam and still degrades in UV finis Texas born and bred |

||||

| Bug Bit Newbie Joined: 09/11/2006 Location: United StatesPosts: 2 |

It is a 7 1/4 saw blade dual rotor. I used #24awg. 350 turns per coil, 9 coils, 12 mags per rotor. It will hit 12 volts at about 50 rpm but any amps are gobbled up going through all that small wire  . sure is fun watching it turn though. . sure is fun watching it turn though. |

||||

| wayne Newbie Joined: 14/09/2005 Location: CanadaPosts: 29 |

Hey Guys How about a few broken Lenz pics'. I really had a bad last week with large wind storm. Trees down and most of my babies are broken.

Starting Over Wayne |

||||

| thefinis Regular Member Joined: 23/08/2006 Location: United StatesPosts: 53 |

Wayne is that the unit that got taken out by a flying tree branch? What kind of flashing is that? If it is sheet metal I have found al flashing cheaper than sheet metal but the biggest width is 20 inch. You can design for lots of things but when the trees start flying through the air you just have to hope for the best. Hope you have a shop as it looks like cold weather is setting in up there. Finis Texas born and bred |

||||

| wayne Newbie Joined: 14/09/2005 Location: CanadaPosts: 29 |

Finis I saved the F/P one above by cutting off the lower blades for now. And it is flashing I used, but easy to get bend with flying stuff. I wired this F/P like this http://www.thebackshed.com/windmill/FPRewire.asp and find out don't really get alot of power when the F/P Lenz spins. Don't know what to do and how to rewire for less than 150 RPM's for some power. Once its over its clog start it spins but need a good gust to start. Just don't know right now? Wayne |

||||

Trev Guru Joined: 15/07/2006 Location: AustraliaPosts: 640 |

You have 2 poles in series, This requires 180+ rpm to get any charge. If you find the middle of the standard 14 pole series and just cut in half, providing 7 poles in series and then take of power from both ends of the 7 poles (delta), you will start to see some charge at around 65 rpm. Of course, this increases the voltage somewhat in higher rpm. My lathe has set rpm gears - 13v@65rpm, 37v@180rpm, 40v@200rpm, 48v@235rpm, 67v@330rpm. I've used this with up to 70v open circiut, charging 12v batteries. Trev @ drivebynature.com |

||||