|

|

Forum Index : Windmills : Ferrite VS Neodymium strength

| Author | Message | ||||

| shawn Senior Member Joined: 30/03/2010 Location: New ZealandPosts: 210 |

That is a cool looking machine there niall glad its not near me i would spend to much time staring at it!!

So maby a large ceramic axial flux mill might be worth looking at I do remember reading one of your old books Hugh I think it was a car or truck drumbrake type but canot remember if it had ceramics? If I went this way (ceramics) it would be fun to do it cheap and get as much power as i can out of say a 3/4 m blade set mmmmmm wonder how big the mag plates would have to be ? I still have plenty of 1.6 mm wire for the stattor. no fancy lazer cutting and more chainsaw blades what fun !! IT ALWAYS BUGS ME HOW MUCH MY BIG MILL COST THIS IS WHY I STILL LOVE LITTLE F&PS |

||||

| scoraigwind Newbie Joined: 23/09/2009 Location: United KingdomPosts: 21 |

I built a lot of axial flux ceramic/ferrite alternators before I got turned on to neos. For example the design that's going around the web called the 'PMG manual' that I did for ITDG in year 2000. I also earlier built a brakedrum design and sold plans for that but the curved stator was a cow to make. It was actually Gordon Proven who suggested I simply put the coils in the gap between the ferrites on the brake drum and the motor lamination stack in the middle and it worked pretty well. No need for teeth. His big axial flux 'toroidally wound' alternators have no slots or teeth in their laminated core either. It's just a strip of steel wound in a spiral. It's a neat design. North poles face north poles and south face south. Flux travels tangentially along the core. Not original of course all this stuff was figured out over a hundred years back. This configuration concentrates the flux from a large area pair of magnets into a smaller area cross-section of steel core. The prototype of the 6k proven was erected here on scoraig, and worked from about 1998 until last year. It is a nice machine although it had an awful lot of teething troubles for the first five years. They went on to build an even bigger one which also had its problems but the 6k is relatively reliable now. The main thing I would miss about going back to ferrite/ceramic magnets is the braking torque of neos. It's great to be able to stop the machine dead no questions. But to be honest otherwise I would not miss them that much. I am not a big fan of high peak power and it's usually just a nuisance in many ways - stalling the blades and burning out the coils. Nice steady low power output is what you need for battery systems and good reliability. Big heavy alternators are easy to cool and once they are up there it doesn't really matter how heavy they are. My latest 'Recipe Book' is all about neo magnet alternators and they do work really well, but with the price of neo going up and with the hassles I have had with the material over the years, I reckon ferrite is/was not a bad way to go. I plan to produce up-to-date plans for a ferrite range of machines similar to the recipe series. They would be especially good for developing world sites where low cost and durability are key things to consider. F&P motors are obviously very popular down there because they cost so little and all that but they are limited to a certain size and there are some issues with losses in the core. For me it was a wonderful development to get away from converting off the shelf stuff to building what I want and making it do exactly what I want rather than making compromises. I don't look at this forum as often as I should and I miss a lot of stuff but I thought I would just dive in and make a comment about the pros and cons of ferrite versus neos. Sorry for rambling. Hugh Piggott |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Feel free to drop by and ramble anytime Hugh

The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

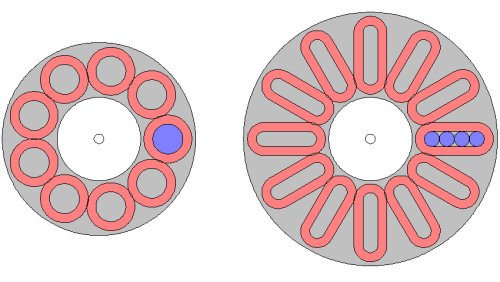

Just been thinking about ferrite magnets. I had a look at some of the suppliers magnets shapes and sizes in ferrite, and some of the shapes have potential in a axial flux alternator. I found one that was a cylinder 25mm diameter and 22mm long. Its length gave it a bit more strength over the 10 to 12mm thick cylinders. I was thinking they could be placed side by side to give a better magnet shape. See the pic below, to the left is a common layout using 50mm Neo magnets, 12 magnets per side on a 9 coil stator, 3 phase. To the right is 4 of the ferrite magnets in a row ( all poles facing same way of course ) to give a 100mm by 25mm magnet. This overall magnet shape lends itself to a better coil shape. The coil is narrower, meaning you can fit more coils around the stator, with the same inside diameter as the Neo magnet stator. We get 12 coils, and would use 16 sets of magnets per side. This also means a higher AC frequency for a given RPM. We also have more of the coil under magnet, the ends are shorter compared to the round coils. So by going to ferrite we loose magnet strength, but we do gain frequency, and a better coil shape. These gains would still not give us the power of the Neo magnet alternator, but we could definitely get a alternator with respectable power. There are other advantages I can see too, like the magnet plates wont need to be as thick ( heavy and expensive to cut ), 4mm steel could be used instead of 10mm, at a guess. And the stator is bigger, so will dissipate more heat. Just thinking out loud.

Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi All I was having a look at whats available and came across a 50 x 75 x 20 it dosent have any specs on it specific but sounds interesting. Cost about $14 but in lots of one hundred $9 anyone interested in coming in on a bulk buy? I need 32 for my project. I might purchase 2 just to get a look at them, but sounds good for my project. All the best Bob Foolin Around |

||||

| shawn Senior Member Joined: 30/03/2010 Location: New ZealandPosts: 210 |

Glen we were thinking along the same lines you are better with drawing though! also thinking out loud we could use old saw blades for mag plates even two each side for thickness zero cost build except for the mags and tower? I seem to have collected mill building materals around me and seems a waste to not use them. also thinking out loud can f&p ceramics be ground? maybe glue 3 together grind flat and repete using 6 for one big mag on glens design? shawn OOH yes I win the idiot of the week award the f&p mags have north and south poles on th same side beside each other just rememberd the dust on them   |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Grinding ferrit magnets is very difficult to do, they are hard, will blunt any cutting tool, and get hot when you grind them. You can crack/chip them into shape. The F&P's ( later model ) are 4 magnets in one block anyway, the poles change as you go across the surface, so they wont work as a large single pole magnet. If you have the older hub with the individual 22*10mm rectangle magnets, dont go pulling them out!, those old hubs are rare and give slightly better power then the new hubs I believe. This was the magnet I was looking at, I got my figures wrong, its 22mm diameter and 25mm high, which is better anyway. http://aussiemagnets.com.au/product/-22-x--25mm-Rod-%28Ferri te%29.html. Had a pull strength of 2kg, 1800 gauss, for $1.15 each. To compare, a 30mm dia 10mm thick only has a pull of 1.15kg, no gauss listed, and cost $1.65 each. http://aussiemagnets.com.au/product/-30-x--10mm-Disc-%28Ferr ite%29.html The taller 22mm dia 25mm high magnet has a lot more pull power. Hey Bob, just check with the manufacturer which faces are the poles. Some of the rectangle magnets are polarised through the ends instead of through the wide faces. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glenn I have emailed for more info on the magnets, but sounds good, to buy a set including postage is only $350 including GST and postage for 32 magnets. if they are suitable I will add a link to the supplier. Do you know a reasonable priced supplier for 2mm or bigger wire in Brisbane? All the best Bob Foolin Around |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

it seems that proven machine has "an ace in the pack " with its laminate stator design working with ferrites ....N facing N poles and toroid coils cooks my brain nicely Ed lenz,s site has a ferrite axial build (micro wave mags) with data on its performance ...not a dual rotor machine ....but very interesting reading toroid coils ...mmm ...curiosity killed the cat ...it,d be interesting if anyone had an expired proven alt to autopsy ...

maybe one will turn up eventually .....  niall |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hi Bob ,, and any other crew that have investigated the LG motor and Neo mags for it. I've a couple of LG motors dismantled ,ready for the conversion to Neo ..If you get a price on something that will fit ,,I'll be ineterested in getting a pack to suit the LG . Best luck Bruce Bushboy |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Bruce The ones I am using is the 10x10x5 blocks I was going to use three per pole but I now think that will saturate the stator so am coming down to two magnets an each pole according to my calculation that should be 2.5 times stronger than the original magnets They are available through frenergy magnets at 65 cents each I think. Being 5mm thick they have about .75 mm more air gap, but that should be compensated on how much stronger they are. All the best Bob http://www.frenergy.com.au/products/Block-10x5x10-mm-N45.htm l Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi all A force calculator for neo magnets, very interesting. Bob http://www.frenergy.com.au/pages/Magnet-Force-Calculator.htm l http://www.frenergy.com.au/pages/Magnet-Force-Calculator.htm l Foolin Around |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Glenn I got the reply about the magnets. Hi Bob, Yes it is magnetized through the thickness. Sounds good to me, I am nor sure about the strength compared to a neo but as it is larger and thicker shouldn't be to much difference, come back any one with a comparison. All the best Bob Foolin Around |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Hello Bob .. I was just browsing through e-bay and under "long wire" as in long wire antenna ,, I found you can buy brand new enamelled 2.11mm copper wire by the Kg . $28 per Kg he says 3 Kg's is approx 100m. Maybe you can get it cheaper ,haven't looked ,just came across this and remembered your post. Bruce Bushboy |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Bruce Thanks for that I will have a look into it today. All the best Bob Foolin Around |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

There are plenty of small businesses around that manufacture small transformers, and others that rewind electric motors. They all carry a large inventory of enamelled copper wire in a vast range of sizes. The telephone book is guaranteed to find someone fairly close to you. The wire is basically measured in mm (copper diameter), and it is sold by the Kg. There are two different types of polyester imide insulation commonly used. The cheap and nasty stuff is pink, and rated to only 200 Celsius. The manufacturers love this stuff for low temperature applications, because you can solder it without first stripping off the insulation (it melts). The good high temperature polyester imide insulation is brown, it is a bugger to strip, but that is what you should be using. This is used for power transformers, motors, and other serious duty power applications. Standard wire tables will give you the length per Kg, resistance per metre, and current carrying capacity. Everything you need to know. So you walk into your local motor or transformer rewinder and ask for " 1.5Kg of 1.2mm high temperature polyester imide wire" (or whatever) and he will know exactly what you are asking for. If you can supply a drum onto which he can wind that wire for you, so much the better. Otherwise there may be a problem. You may have to pay for the smallest amount of wire he has on an existing larger drum, which may be a lot more wire than you need, and you may have to also pay for and buy the drum. The copper wire manufacturers supply the wire in bulk on large drums, which are always returned to the manufacturer when empty. There is a fairly hefty deposit involved. So your friendly motor rewinder is not going to supply a plastic drum, unless you pay for it, and for small lengths of wire, the drum will cost far more than the wire. My rewinder that has been a personal friend for over thirty years just says take the whole damned drum, use whatever you need, and bring back whatever is left when you have finished. A fantastic arrangement for me, but he sure would not do that for someone he did not know. So know exactly what you want, and have an empty plastic drum with you, and any required length of any diameter wire is dead easy to obtain. The price varies a lot, but if you do not need much, sometimes, just getting exactly what you need can be more important than the actual final cost. Cheers, Tony. |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

G'day Guy's, Amack asked me to get a price on 25 off 50x15 N50 round neo's from my china supplier. When we got 150 of them they worked out to about $10.50 including shipping and import duty etc. I near fell off my chair when I saw the new pricing. $25 each for the same magnets and that doesn't include shipping. The reason I was told of the price hike is the cost of rare earth materials has gone thru the roof. Cheers Bryan |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Yep , I've been following the share price of LYNAS .. this mining company in australia is into rare earths .. The Chinese are being very carefull of how they sell their rare earth products ,,seeing they are the major mine,or of rare earths and the world demand is skyrocketting... Bruce Bushboy |

||||