|

|

Forum Index : Windmills : AXFX Advice

| Author | Message | ||||

AMACK Senior Member Joined: 31/05/2009 Location: AustraliaPosts: 184 |

I am looking for a little advice on magnet spacing and mag size for a mill? The 2 metal disks i have are 8 mm thick.

I have decided to give one a go. AMACK *Note to self 1. Make it thick 2.Make it heavy. 3.Make it stronger than it should be. 4. Don't rush the first job as the second job will cost more and take mor |

||||

niall1 Senior Member Joined: 20/11/2008 Location: IrelandPosts: 331 |

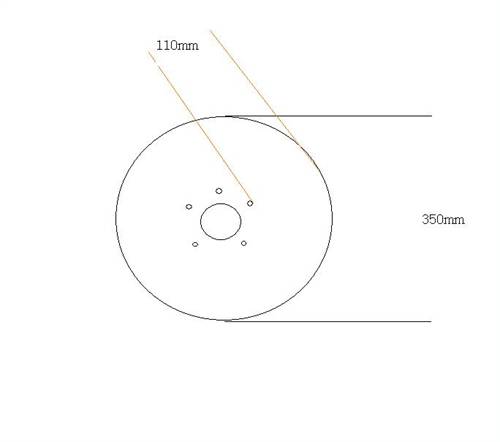

Hi Amack i looked up Hughs specs on his machines ...its cheating a bit ...

at 8 mm and 350 D thats pretty close to his to his 2.4M machine ...the 3M machine uses 10 mm disks at 350 D i,m really hoping others with experience can come in here and discuss the magnet choice and coil (turns) layout .... maybe 12/9.... nows the time to figure it out ... ......  niall |

||||

AMACK Senior Member Joined: 31/05/2009 Location: AustraliaPosts: 184 |

Thanks Niall, I think you are close to what I had in my mind to do. I have had a look at Hughs book and I do plan on using 12/9. I would like it set for 24 volt as that is the system voltage I run.. I have used a Holden hub and a 50X50 mm stub and intend to make the frame and stator after a bit more home work has been done. I need to talk to Downwind about coils as he has had a lot of back ground info on them. AMACK *Note to self 1. Make it thick 2.Make it heavy. 3.Make it stronger than it should be. 4. Don't rush the first job as the second job will cost more and take mor |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

12/9 is the best all rounder. If you stick to Hugh's plans for the magnet spacing and coil layout, you cant go wrong, he's built a lot of machines and knows his stuff. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||