|

|

Forum Index : Windmills : Mast to guy wire - which clamp?

| Author | Message | ||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Hi, One solution to connect the four guy wires to the pipe of the mast (tower) is to weld on four nuts (for the threads) and then buy those screw-in "eyelets" to connect the wires to. I have come across (in my dreams?) split-clamps for a more elegant solution. Do they exist at all and if so, for purchase in WA? By them I mean two halves , which bolt together on the pipe and have four eyelets. My terminology might be wrong. Thanks. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| windlight Guru Joined: 03/03/2007 Location: AustraliaPosts: 331 |

Dom I have never seen what you describe but do know that I would be reluctant to rely on something that is not welded to the tower, Murphy says a clamp WILL come loose. I would love to catch up if you are going past. Allan "I like this place and willingly could waste my time in it" - (Act II, Scene IV). |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Thanks Allan. Might drop in one day! Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| imsmooth Senior Member Joined: 07/02/2008 Location: United StatesPosts: 214 |

This has worked out very well for me. guy wire attachment for tower |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

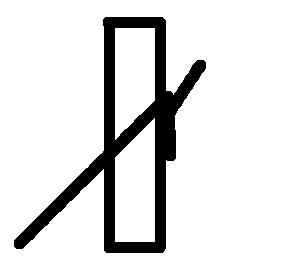

This is what I use. Only one guy is shown for simplicity. The guy goes right around the tower inside plastic hose and the welded peg stops it going down.

|

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Dom I have used exhaust pipe clamps on the past with success, need to replace the nuts with nylock nuts. All the best Bob Foolin Around |

||||

| Greenthumbs Regular Member Joined: 05/12/2008 Location: AustraliaPosts: 40 |

Hi guys, I used chain links cut in half then welded to a outer pipe which was too big so I cut it lengthwise then welded it together after clamping it hard up to the mast. Then small staggered welds top and bottom to hold the outer pipe from moving. The idea being that the less you weld to the mast the less weak points you create. I like imsmooth's idea too but my idea is a little less sophisticated. Robb I hope you have staggered the welds up and down the pole a little so you did not create weak points. I did something similar with the cable that pulled the whole tower up into position. Dom I know exactly what you mean, they use them on 4WD bull bars. I was going to do it the same way but they do not do them with long threads. I wanted to put the thread right through the pole like a bolt and put a hude washer on the other side with a nut and lock nut. Welding a nut to the pole is dangerous as it could come undone. My father in law used to be a ham radio operator and made many towers, so high they had to have a flashing light on top for planes. He said that it was most important not to weld all around the pole because of weakening. Every weld is a weak point. Oh and note the bits of wire twisted through the D shackle bolts. That is a safe gaurd for vibration. I did the bolts up with a spanner and dought they will come undone but my father in law said I would be suprised what could come undone. So I followed his advice because he is rarely ever wrong! My tower and mill went through a massive storm a few weeks back the weather station I owned had its cups blown off. The mill had all its blades and tail ripped off too. Just a stump on a pole left.

But the 13.5M tower did not move at all. I live at the top of a hill and we get massive gusty winds so I hate to think what the max gust wind was. My weather station has recorded on two separate occasions wind gusts of just over 300Km. It is a ebay cheapy so I dont know wether to belive it or not buit it has happen two different times.... Unfortunately the weather station was not recording at the time of the storm as it blew up a couple of weeks before when water got into the transmitter. It would have been nice to know what the max wind speed was at the hight of the storm. Damo |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Damo Sounds like a good spot for a turbine. All the best Bob Foolin Around |

||||

| JimBo911 Senior Member Joined: 26/03/2009 Location: United StatesPosts: 262 |

Hell' why not give this a try.

Jim |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

They are all at the same point but it is thick wall water pipe and has been up for ~15 years now. The other thing is the guys are not 100% tight giving some room for expansion / contraction etc |

||||

| kevindion Regular Member Joined: 28/07/2010 Location: ChinaPosts: 59 |

you know what?am not going to build tower for my windmill. |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Thanks for the many answers. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| brucedownunder2 Guru Joined: 14/09/2005 Location: AustraliaPosts: 1548 |

Dom, what sort of guy wire are you using . That stuff that Allan was getting rid of ?.. If so ,, it's easy to terminate .. I'll wait for your reply ,then tell you with photos how to terminate it.. Bruce. Bushboy |

||||

| Barry T Coles Senior Member Joined: 30/07/2009 Location: AustraliaPosts: 109 |

Hi Dom Is this what you are thinking of:

This is where I found them. Pipe clamp They are available & i've seen them in use on radio masts, if you use one you should weld some cleats on the mast below the clamp as insurance to prevent it from slipping down, these things do hold on really tight but I would still go with the cleats. Hope it helps. Cheers Barry I need to learn from the mistakes of others. I dont have the time to make them all myself. |

||||