| Author |

Message |

trobador

Newbie

Joined: 07/08/2010

Location: United StatesPosts: 6 |

| Posted: 11:38am 07 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Had this old generator(1930)for a few weeks,I got from ebay 3 panels made by wincharger the main is a WINCHARGER CORPORATION SERVICE PANEL MODEL #326,now question,Can I use this panel with my wincharger 12 volt or is it for a diferent unit from the same company(32V,40V or may be 6V)I have photos of the 3 panels

Thanks for your help,Trobador |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 12:41pm 07 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

1930.......Hell im not that old and many here will not be,(or want to be) so best you help us out with some photos and more data of what you have.

Your question is a bit like will part "A" work with part "X".......bugger if i know what "A" is, lead alone what "X" might be.

Please Explain.

Pete.

Sometimes it just works |

| |

trobador

Newbie

Joined: 07/08/2010

Location: United StatesPosts: 6 |

| Posted: 07:44pm 07 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

A=panets

X=wincharger 12V

Question=can i use the panels with this generator(panels and generator are more than 60 years old)?,I am 66 years old

I send the photos, hope it help

Thanks,Trobador |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 12:41am 08 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

I really dont know myself, but it looks like you have panels from 3 different windmills.

The one you show looks to be the same as the one in the photo on the manual.

Others here might be more tuned in on the earlier Windcharger systems.

If i am correct the wind charger is self governing and you could just use a later electronic controller. (even a solar controller)

I am guessing the silver box on the panel is a voltage controller that is simular to the early voltage regulators used on cars with a double relay type arrangement.

I dont think these systems used a diversion load and the voltage regulator just cut in and out to maintain battery voltage.

As the mill is self governed it is allowed to sipn unloaded and the blade pitch is adjusted to control the mill rpm.

For this reason i would think a solar battery controller would work with this mill.

Lets see what others have to say.

Pete.

Sometimes it just works |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 12:47am 08 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Trobador

This kind of stuff is simple and it looks like it is salvageable, you will need a circuit diagram of the regulation system of the generator to get it going, I used to work on this type of equipment many years ago and it seldom dies.

Check the things for continuity with your ohm meter and check for shorts to earth, the left hand board looks like the regulator for the mill, in the box on it there should be a isolator relay and a regulator relay, check the coils on both for continuity and check the points to make sure they are clean, clean them with a piece of cardboard to clean their surfaces, if badly corroded use a piece of 600 grit wet and dry with some contact cleaner spray.

The clips are for the old type fuse, cant get them any more here, but you can connect them with a piece of fuse wire to get it going.

The center relay may be an isolator relay for 32 volt, the third panel looks like the battery feed panel.

Best of luck with getting it going.

The generator can be checked by putting a volt meter on the output and turning it by hand. Give it a full service Brushes, Commutator clean, New bearings, or repack the old ones if they are still in good condition. Check the propeller for damage , cracks and Balance re finnish with good quality marine paint and re balance, check the speed control vanes for mechanical damage and wear and freedom of movement. be sure balance is maintained.

All the best

Bob

Foolin Around |

| |

trobador

Newbie

Joined: 07/08/2010

Location: United StatesPosts: 6 |

| Posted: 07:53pm 08 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

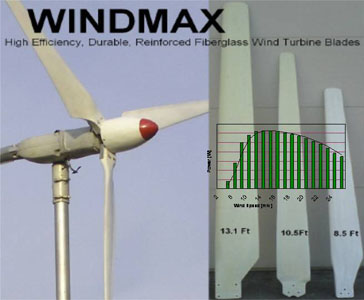

Thanks for the help Pete and Bob,after my post with the photos i called the past owner and we are going to meet today,he says that he has a broken panel and that is why he did not give it to me,The generator is in excelent condition with new brushes,he had this unit for the last 25 years and gave me 2 props and one is in perfect condition but I will like to use a new set of 3 bades to see what it does at higher rpm,the gen turns very easy and i will be checking it very closely,It is very heavy(60 to 70 pounds)so i am going to use a tower with a 3" diameter tube may be 30 feet;I will let you know how the panels came out when i get around to go over them.

This is just a first test with a windmill generator,what i whant to have is a 2 or 3 kw one so I whant to see the reaction of my stockup neighbors with this smaller unit before i get to the big one;By the way i am all the way in Miami,Florida

Lots of thanks for your help

Trobador

PS:Photos of 3 props

One Set of 3 Low Start-up Wind Speed, High Efficiency, Light Weight, Load Balanced, Reinforced Fiberglass Commercial Wind Turbine Rotor Blades

|

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 08:13pm 08 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Trobador

Sounds good, if you go for the three blade prop it may be useful as a 24 volt unit for more efficient usage, I would get a solar type MPPT regulator as Pete suggested, for 24 volt 50 / 60 amps, and set up the old stuff for museum pieces, at the higher revs and a larger 3 blade prop it will pleasantly surprise you, these are good old units, made to last, and if maintained properly will keep going for many years yet. You will need a power dump setup to avoid cooking the batteries and prevent over speed, as you won't have the vane governor setup with the three blade bigger prop.

Keep in touch and tell us the good news.

All the best

Bob

Foolin Around |

| |

trobador

Newbie

Joined: 07/08/2010

Location: United StatesPosts: 6 |

| Posted: 08:20pm 08 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Roger,we will,one more question ,What will this props do to de voltage, the gen is ony 12 volt?

Trobador |

| |

Downwind

Guru

Joined: 09/09/2009

Location: AustraliaPosts: 2333 |

| Posted: 02:16am 09 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Im not sure if all is very well understood here with the 3 blade prop.

For starters, a 3 blade prop will normally spin slower than a 2 blade prop but will have greater torque.

Also a bigger prop area dont mean higher rpm, higher torque yes.

As Bob said with the 3 blade prop you will have no govenor and will need a different charge controller and a diversion load (Dump load)to control the mill or it will reach self destruct speeds.

My advice would be leave the 3 blade prop alone and stick with the original 2 blader until you have a much better understanding of what you need and how all this works.

Pete.

Sometimes it just works |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 06:34am 09 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Hi Trobador

Voltage is a term rather than a standard in this form of generator, if you spin it a bit quicker it will give a lot more volts, if you where to measure the unregulated off load volts of the generator now at its rated speed it will be around 35 volts, if you spin it 15% faster it could go nearly twice that,

.

So the thing is to let it spin a bit faster and draw half the amps at twice the volts and the watts will stay the same. Or you may find as I have that it will produce the same amps but at twice the volts giving twice the watts. Its a matter of trial to see what happens, but it will go along these lines, as I have done that in the past many times.

I think Pete's suggestion to get it going as is to learn your way is a really good suggestion. Just tighten the governor springs a bit to let spin a bit faster and you will see what I mean.

All the best

Bob

Foolin Around |

| |

trobador

Newbie

Joined: 07/08/2010

Location: United StatesPosts: 6 |

| Posted: 06:03pm 09 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Thanks again Pete and Bob,taking your advice i will start using the original prop and tinker with the springs of the controler for a wille and on the side work on a newer type charger controler with at minimun 50 amps plus a diversion load (Dump load)to control the mill and work on the new props at a later time.I will let you know how is going alone,if I have and important question i will send you guys a PM

Thanks a lot

Trobador Edited by trobador 2010-08-11 |

| |

VK4AYQ

Guru

Joined: 02/12/2009

Location: AustraliaPosts: 2539 |

| Posted: 01:29am 10 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

Have fun cause thats what it's all about.

Bob

Foolin Around |

| |

trobador

Newbie

Joined: 07/08/2010

Location: United StatesPosts: 6 |

| Posted: 06:55pm 10 Aug 2010 |

Copy link to clipboard Copy link to clipboard |

Print this post |

|

i am going to order one WINDMAX 2KW,the price is very nice shipped to Miami around $1500 with shipping,yes i know it has issues but i will be changing the bearings and moding the props to more quiet operation and since i will be seting the tower for the Wincharger 12V i am going to build it to the 2KW specifications wich is much hevier,i will put it in storage untill redy for it, the new 2Kw is going to be like $4000,so like mony in the Bank(no vacation for the Wife)By the way you guys are so nice that if you come around Miami and let me know in advance i will get you a deal in Miami Beach (almost close to free)

Photo of the 2KW:

Every wind turbine is made differently. WindMax V20 Wind Turbines are proven systems deployed worldwide with good performance track records. WindMax V20 Wind Turbines feature low start-up speed and good performance at low to medium wind speed. WindMax V20 Wind turbines are made professionally in an ISO certified factory. They are CE certified and passed factory quality inspections. Recommended working wind speed range is from 5 mph to 30 mph. Overspeed control mechanism is combination of mechanical furling and controller electrical braking.

WindMax V20 Wind turbines are neighborhood friendly with low noise level. Please call us for noise measurements.

This is there ad but I know is not so about the noise

Thanks

TrobadorEdited by trobador 2010-08-12 |

| |