|

|

Forum Index : Windmills : CNC and Motor Conversions

| Author | Message | ||||

| WXYZ Newbie Joined: 30/04/2006 Location: CanadaPosts: 20 |

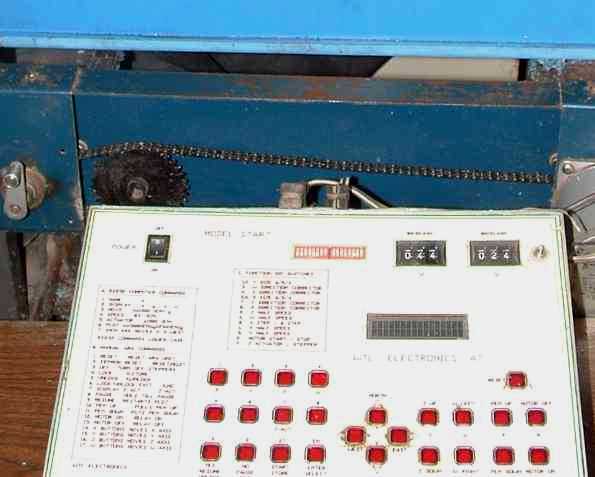

This is one of my first cnc machines.

The controller was made and programed by my brother Bill.

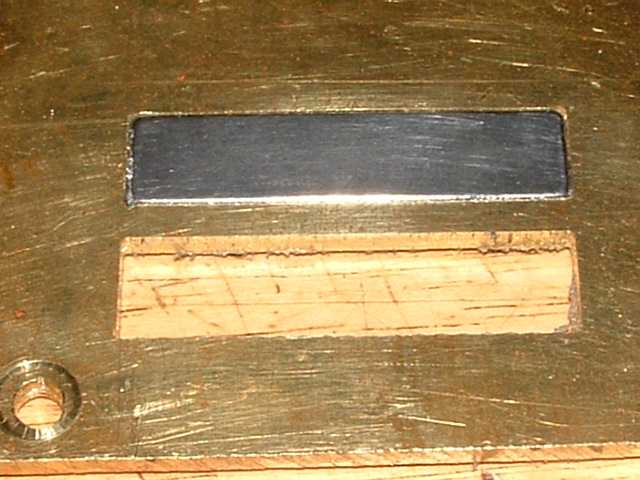

I added a horizontal indexer and started on an old motor conversion. My first test cuts are to see if the neo magnet will fit correctly.  Nice fit Nice fit . .

The cutting starts. I use a 1/16" solid carbide, two flute cutter running at 50,000 rpm. The cutting fluid is 25 ml of standard dishsoap and 1 liter of water. 24 N40 neo magnets will be placed into this cage (NSNS) to give me a 12 pole 3 phase genny.  This is the finished cage that will hold the magnets. This is the finished cage that will hold the magnets. The stator came from an old 1/&1/2 hp that was fried here is the stator now skewed 10 degrees. I will wind it three phase. The stator came from an old 1/&1/2 hp that was fried here is the stator now skewed 10 degrees. I will wind it three phase.  The insulating material is .01 dacron-mylar-dacron. I figure that the output will be around 500 watts at 280 rpms. I will post more on the motor conversion as it develops. The insulating material is .01 dacron-mylar-dacron. I figure that the output will be around 500 watts at 280 rpms. I will post more on the motor conversion as it develops.

Enjoy. Joe. "Failure is an option." |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Be interresting to see how that alternator performs. I have a couple of large induction motors I'm keeping for the day when I have some copper to rewind them. I like the rotary miller. I'm tempted to try routing aluminium on my router again. My first attempt didn't work too well, but my spindle speed was only 3000 rpm. I've since leaned this is way to slow. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| WXYZ Newbie Joined: 30/04/2006 Location: CanadaPosts: 20 |

Gizmo, The head on this unit is made from a 220v vacuum motor. I run it at 110v. I draws 400 watts, so it doesn't slow down when it is cutting. I can adjust the cutter to be within one thousands of an inch but I find that they last much longer with more run out. I have a speed controller in line with the cutter. I cut abs, poly and nylon very slow 1000 rpm. Most Plexi-glass at 25000 rpm. When I cut aluminium or brass there is a steady drip of the cutting fluid. I also cut metal at the maximum speed. The poly box under the cutter catches the mess. Up to 1/4" thick aluminium or brass I cut with a single pass. I drill through then cut away. End milling is real hard on these small cutters. The controller has backlash thumb wheel switches. This was the single improvement that has made the machine really accurate. This machine does not have the plastic slides that the new ones have. You asked if there was any slop in the slide. The aluminium cover is bent and this adjusts the play in the slide. I would use no other slide system in any cutter machine, they work excellently. I had bronze thread in this old machine they lasted less that a year. I replaced them with nylatron in 1998. Joe "Failure is an option." |

||||

| WXYZ Newbie Joined: 30/04/2006 Location: CanadaPosts: 20 |

The rotor with all the magnets installed.

A .01" non-magnet stainless steel skin covers the magnets. I built the plywood box to hold and protect the rotor. "Failure is an option." |

||||