|

|

Forum Index : Windmills : Low rpm coreless pmg ?

| Author | Message | ||||

| Cold-smoked Newbie Joined: 01/12/2020 Location: NorwayPosts: 5 |

Hi all. I plan to build a vawt, similar to the smallest Ecorote turbine. So I was wondering if anyone here has any experience with the low rpm coreless pmgs offered from places like aliexpress, alibaba ? https://www.aliexpress.com/item/32901117971.html?spm=a2g0s.8937460.0.0.74ab2e0eKfA4eQ The F&P motors that many here experiment with, are not easy or cheap to find here. So I´m willing to pay for a ready to run motor - if I only knew that quality is good. The specs on the motors offered from China looks good, but I don´t really trust the ´reviews´.. Thanks, V. Edited 2020-12-02 04:43 by Cold-smoked |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Welcome to the Forum CS. According to the specifications it needs to turn 250 rpm to deliver full rated power. That is just over four turns per second, its not that low an rpm. Quite possible with a small diameter multi bladed horizontal axis turbine, but not sure that a vertical axis machine can go quite that fast. It may require a gearbox..... Edited 2020-12-02 07:28 by Warpspeed Cheers, Tony. |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

Oops, posted in the wrong thread. Edited 2020-12-02 08:32 by Warpspeed Cheers, Tony. |

||||

| Cold-smoked Newbie Joined: 01/12/2020 Location: NorwayPosts: 5 |

Thanks, Warpspeed. This is the 2.8 kw Ecorote 2.3 m diameter turbine. By the looks of it, it's running pretty fast in this video : Ecorote 2.8 My plan is to build something similar to the smallest Ecorote, which is ~1 m diameter and rated at 300W at 10 m/s winds or 600W at 15 m/s. So I`m thinking that maybe that 250 rpm motor is about right for my project, but they also offer 150 and 200 rpm motors at 500 W. low rpm Thanks, V. Edited 2020-12-02 08:39 by Cold-smoked |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

I suppose the thing to do would be to put up the turbine first, and see how fast it goes, in your typical local prevailing winds, then start thinking about relevant rpm. I spent a couple of years in the Antarctic, and the winds down there were nothing like the lack of wind we have here here in suburban Melbourne. High latitudes and cold air seen to make a big difference ! Cheers, Tony. |

||||

| Cold-smoked Newbie Joined: 01/12/2020 Location: NorwayPosts: 5 |

That´s probably a good idea. I live above the arctic circle, and this time of year we get zero from solar - but it´s often quite windy. |

||||

| WindyOne Newbie Joined: 09/11/2012 Location: United StatesPosts: 3 |

Some questions that you need answered are ... a) Does the PMA have Low Temperature grease for the bearings? b) What is the maximum Vertical / Axial Load limit? c) What is the maximum radial load? ( ie max rotor height x wind speed ) Properly designing a DIY VAWT is quite complex. Finding someone who has actually purchased that PMA, from that vendor will be unlikely... |

||||

| Cold-smoked Newbie Joined: 01/12/2020 Location: NorwayPosts: 5 |

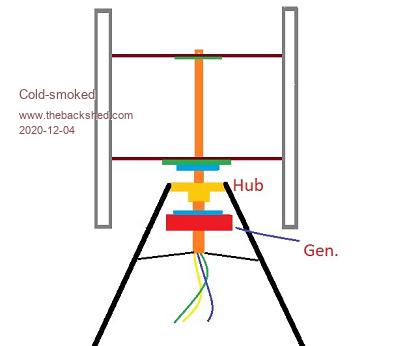

Yes, I would pick it apart and replace grease and so on. I plan to build it so that the turbine structure rests on a bearing hub of its own, to try and increase durability and ease of maintenance. Edited 2020-12-03 03:20 by Cold-smoked |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That would definitely be the best approach. Have a driveshaft or a coupling that does not transfer any of the major loads onto the generator bearings directly. That would also facilitate the removal of the generator for maintenance or repair. If you can have all the electrical bits near ground level, that would also be a big plus. Not a lot of fun climbing structures or working on things way below zero. Been there done that... Cheers, Tony. |

||||

| Cold-smoked Newbie Joined: 01/12/2020 Location: NorwayPosts: 5 |

Yes, I guess I could put together a hub assy using a couple of trailer or go cart hub kits or similar - and flanges between the main components. Btw, I noticed that the various versions of the pmgs I linked to are 7.5 to 19 kgs. I believe I saw 17 lbs or 7.7 kgs for the F&P`s.   Edited 2020-12-04 07:36 by Cold-smoked |

||||

| Warpspeed Guru Joined: 09/08/2007 Location: AustraliaPosts: 4406 |

That looks very good. A very strong pyramid type of support structure is an excellent idea, and needed to support the whole thing against the high wind loading, and the inevitable vibration. The vertical rotating shaft could be extended right down to near ground level, and the main weight supporting bearing could be placed down low for best access. You could drive the generator direct through a coupling, but a better idea might be to drive it through a belt or a chain drive, with a drive ratio that could be very easily altered, especially if the generator was bolted to slides to easily adjust the centre distance. There may be some very great gains to be had with an an adjustable drive ratio. If its all kept very simple, with the fewest parts, its not only going to be easier to fabricate initially, but also a lot easier to rebuild if it ever gets wrecked in a storm. Cheers, Tony. |

||||