|

|

Forum Index : Windmills : Vertical axis windmill

| Author | Message | ||||

| pengyou Newbie Joined: 21/05/2018 Location: United StatesPosts: 1 |

I hope the subject is not misleading. I am shopping for land now and most of the land I am leaning towards has a healthy flow of wind at least 20 hours a day almost every day of the year. I compare this to using pv cells to generate electricity, which would have, at most 5 hours of useful light in the winter. It seems to me that using wind would require me to have a smaller battery pack than pv cells, therefore reducing my upfront costs. Is my thinking correct? am I on the right track? Secondly, If I entered into a situation that gave me excess electricity I could use the excess to generate hydrogen from water, store that and use it for heating, cooking etc. Hydrogen gas can be injected into either diesel or gasoline engines to improve economy. Is that reasonable? Finally, I have read on most pages that horizontal shaft mills are more durable than vertical shaft mills. True? A generality? I have read a couple of websites that state that recently, because of new materials, etc that this may not be the case anymore. I am particularly interesting in this question because I have also read that vsm can be used at higher wind speeds. True? Don't be afraid to throw links at me - I am especially fond of Jimmy Deans ;) I am hoping that I can get enough info from this post to help me structure and direct my research into this topic, and to give me a good overview. I'm not afraid to get my hands dirty with digital dirt! One final question: with wind turbines, does the concept of sprung weight become important at some point? |

||||

| electrondady1 Senior Member Joined: 12/02/2009 Location: CanadaPosts: 208 |

i live in town so wind is just a hobby with me . most guys who are seriously off grid use both methods of generation. if you have a wind resource why not use it . you can generate hydrogen with as little as 2 volts, but the more power in the more you get out . storage and safety are the main hurdles. keep the gasses separate . this guy has a series of videos about production compression and usage . he takes precautions.https://youtu.be/llmcU-mZRFs . https://youtu.be/REV739pRNcw DON'T MIX THE GASSES there are lots of people on you tube trying to blow them selves up . i build vertical drag mills. they are less efficient at producing power than horizontal mills. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Not durable, just easier. Most of us who have built our own wind turbines have at one time played around with verticals. And we soon realised verticals make great garden art, because they dont scale up easily. Its all about the area facing the oncoming wind, and its much much much easier to build a larger diameter horizontal than a bigger vertical. Horizontals also run smoother, are less demanding on the tower, lighter, and more efficient. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| George65 Guru Joined: 18/09/2017 Location: AustraliaPosts: 308 |

I have been looking at the same thing, again, this last few days. Been trying to get a handle on the safety ( geez what a dirty word for me) and practicality of hydrogen. I'm not the sharpest tool in the shed but you only have to look at the fact industrially, NO ONE mixes the fuel and oxidizer together to know there must be a GOOD reason why. YT is Full of these people claiming Miracles for Hohoho gas but the only miracle I see is some of these people have been playing with it great Qty for years and are still here to make Vids about it. I really don't know how they manage it. They burn it in torches and even cook stoves and live to mislead others that it's a viable practice. I believe when your time is up it's up but I also believe it's not a good idea to buy up all the tickets you possibly get to increase your chances of winning that particular lottery. I am testing output of Hydrogen production using aluminum and Koh. I have Loads of scrap aluminum, just the solar mounting rails I have is probably 50+ Kg of the stuff and also a Bag of Koh I used for cleaning up Veg oil spills when I was processing a lot of WVO. I have done some experiments in 3L milk jugs and the production looks OK. The upside of chemical production is you only get Hydrogen and are not effectively wasting energy making oxygen you don't want. The aluminum seems to last very well, What I need to see is how far the KOH goes. I have a LOT of aluminum I melted down and ran into a water bath which gives aluminum cornflakes. Perfect for this having a huge surface area for weight. Would also lend itself to Variable production rates. Put the aluminum in a vessel like a length of pipe with openings at each end. Top takes off the hydrogen, Bottom pumps in and drains the Koh solution. Greater the depth of the Koh solution, greater the production of Hydrogen. My plan would be however to store the hydrogen with Probably a batch process. I just made a ground mount frame for 5x 250W panels. It will be interesting to see how much Hydrogen I can get from pumping a KW of power into an electrolysis arrangement. Biggest hurdle I see is how to keep it cool. With the solar aluminium rails came a lot of roof mounting brackets which are all stainless. They will make good electrode plates with the tails trimmed and welded along a length of rod. Few design issues to work out with this like do I have to have as many plates on the oxygen side as I do the hydrogen side or will I limit the power transfer and If I have say 2 25L drums, Can I connect them just with say a 3/4" hose to the respective electrode sides or do I need to have like 4" to get all the power across to get over something like resistance in electrical cabling? Lot's of info on blow up gas but not so much I can find just on Hydrogen. Using solar power like this may not be real efficient but I guess it's more efficient than throwing it away and may give storage advantages without going to the cost and complexity of batteries. |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

Hi and welcome to the forum. I hold the unpopular stand of being a proponent of vertical axis wind turbines. I have built several and the main difference is, horizontal axis wind turbines run fast with low torque, depending on swept area of course, and vertical axis wind turbines run slower, BUT they can sweep a large area by extending blades a long ways from the center and feature massive torque, which can be dealt with in a transmission. The trick is, with both Mills, to make the blades “fly”. This means taking advantage of apparent wind and airfoil design, but of late, I have designed a new blade, which is a symmetrical-section blade that provides both lift and drag. I am in the process of constructing a proof-of-concept model, which when finished, I will video and put on my YouTube channel, then leave a link here. Here is a little teaser about the new blade I have designed: blades can be manufactured in a matter of seconds and are made out of chloroflute, which is called chloroplast in the states. I know what you’re thinking; Hide and watch. . . . . . Mac If one desires more power out of the only thing you have to do is extend the blades out from center, which increases the moment-arm of the lever action on the vertical shaft, as it were. Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

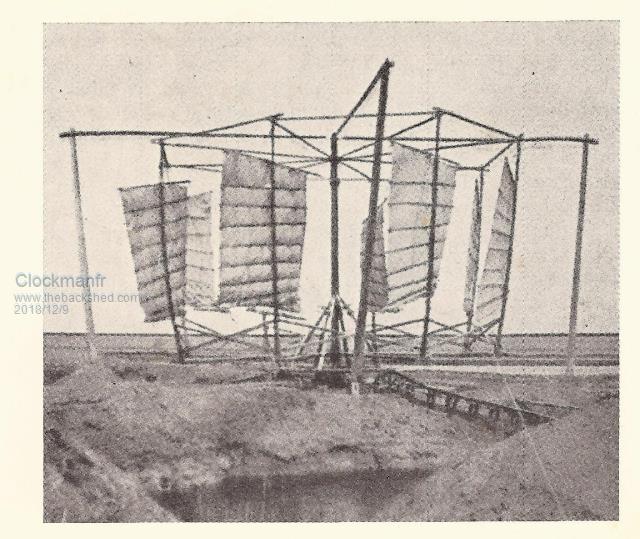

Hi pengyou, I am on this forum, and a fair few others around the World. In the early 1980's, I have played with a Chinese's design VAWT that was around 1000BC and had luffing/tacking Junk sailing boat sails. see pic. Mine was steel construction with a Hydraulic pump operating a big ram with a heavy weight,(Big water tank) that when fully extended operated a switch and realised the energy under gravity to a 2kW generator. My conclusion ...... a lot of work and expenditure and never would get my expenditure retuned, ie it was not a cost effective solution for generating electricity.  I have 3off HAWT 12 footers, 3.7 meter diameter Wind Turbines, they are the ultimate Hugh Piggott design, (40 years in Scotland). Hughs design is Simple, Robust and very cost effective, (about a $1000 per Kw). My 3 have have been up nearly 10 years now, but maintenance can be a 3 day time consuming hassle that needs to be done every year. Even though I do the inspection and maintenance each year, 1. Balancing the blades, re-painting/sealing, or the wild horse on top of the pole will shake it self to bits, NB the first 4 years is not an issue but after that the moisture and rain will eventually get in those blades. 2. Adjusting the blade holding clamp hubs. 3. Adjusting clearance for the stator and rotating magnet discs. 4. Checking the tower cables, untwisting, etc. 5. Checking the phases output is balanced. 6. Repainting the Turbine metal work after removing rust and rust staining. 7. Controls, checking the bridge diodes to ensure all three are sharing the work, and their connections. 8. Diversion controllers, inspect check cable clamping, and very very importantly check the Dump Loads, which with my 3 turbines I need to sometimes dump up to 6Kw in stormy conditions. The connections to the resistor dump loads have a habit of detaching themselves if a screw terminal, think glowing red temperatures, now i use clamp bolt and double lock nut. In Conclusion ....... I do not know many commercial manufacturers of domestic wind turbines, under 5kW, that can give a good trouble 10 year period of running. If I knew 10 years ago what i know now, then i would just stick to PV. I just walk around my PV and inspect from a distance, it just sits there, with no drama. Today, PV is very cost effective against the same energy output of a Wind Turbine. (On other Forums, the Mods remind me that their Forum is a Wind Turbine Forum and my Empirical evidence comments are not helpful, ????) But I do love my Wind Turbines, I think it makes a personal statement, as well as giving me wild RE Power when its overcast raining and gloomy/dull all day, and of course they generate at night. On the Fieldines Forum (USA) a fair bit of work has been done on different types of VAWT's. Everything is possible, just give me Time. The OzInverter man. Normandy France. 3off Hugh P's 3.7m dia wind turbines, (10 years running). ... 5kW PV on 3 Trackers, (5 years) .... 9kW PV AC coupled using Used/second hand GTI's, on my OzInverter created Grid, and back charging with the AC Coupling and OzInverter to my 48v 1300ah batteries. Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||

| Clockmanfr Guru Joined: 23/10/2015 Location: FrancePosts: 429 |

I know of 2 reasonably successful HAWT manufacturers, that use springs on their hubs to counter control the rotating speeds and pull/twist and alter the pitch of the blades depending on the wind force. 1. ..... Jacobs, USA. 2. ...... Proven aka Kingspan. see http://scoraigwind.co.uk/2011/12/gordon-proven/ Everything is possible, just give me time. 3 HughP's 3.7m Wind T's (14 years). 5kW PV on 3 Trackers, (10 yrs). 21kW PV AC coupled SH GTI's. OzInverter created Grid. 1300ah 48v. |

||||