|

|

Forum Index : Microcontroller and PC projects : Wood fired boiler update - LM335?

| Author | Message | ||||

pcaffalldavis Senior Member Joined: 17/10/2011 Location: United StatesPosts: 187 |

Well folks, It's been a few months since I last gave an update on the wood fired boiler. I've been busy mostly working on it. I can say over our hemispherical summer I managed to get the 20 dump truck loads of fill, welded up the boiler from 1/4" plate steel, located it on the site and built a outer shell structure around it and a building for it which also stores about 10 cords of firewood. I have had a few test fires without the plumbing hooked up for circulation and it burns very well. Got the Maximite control panel hooked up yesterday, plumbing finished the day before except for two copper elbows I need to sweat to the heat exchanger. Noticed a strange thing today when I got the temperature sensor in the boiler water and cranked it up for the first time. It would not give a reading higher than 52.6816 degrees C. I have four temperature sensors: boiler water temperature, house air temperature, house water temperature (circulating in the house for bathing and kitchen), and outdoor temperature. I used LM335's for each and calabrated the voltage based on the particular MM which is 3.26v. The other three work fine as does the fourth until the boiler water temp gets up to 52 degrees. Above 52 degrees it won't give any higher readings. The boiler operating water temperatures will usually be between 80 and 95 C, so stopping and maxing out at at 52 won't do. I put on a different spare temperature sensor and got the same results. The sensor is inserted into a length of copper pipe which is crimped at the bottom, soldered, and inserted down into the water under the closed boiler lid. I should have some pics pretty soon when I get time to breath. First I need to figure out why the boiler water temp sensor is not reading higher than 56 degrees C. The boiler water temp sensor is what decides when the air to the boiler fire opens and closes (80 & 95 C), so it is pretty important to get accurate boiler temperature readings so the whole project can be automated. I still have to move 10 cords of firewood into the building and hang the snow fences down the roof-snow shed sides of the house. At least the firewood is already in my yard. We should start heating with the boiler tomorrow when the last two plumbing connections are done. We've only needed wood fires in the house twice so far this fall, but the heating season will soon be upon us full time here. The boiler may be in the manual mode for a while until I get all the bugs worked out. I still have to finish fabricating the air-intake and blower housing but that is a small matter. Until then it is either wide open and a rip roaring fire or closed and smoldering. I have to design a new interface board because I need another relay for the MM. I'm going to use a more powerful 12 V blower fan I got from an old truck at the town dump. It really blows something fierce and will be a great fire blower to get the fire going quickly when the air intake is first opened. The little 12 volt fan I was using from old computers are not powerfull enough so I need another relay, something I was not counting on. Ah well. I'll probably add an extra circuit for temperature sensors too as it is nice to have a spare if one of the circuits should go bad or become problematic. If you have any ideal on what is happening with my LM335 boiler water temp sensor drop a post. Hope you all had a great winter! Ours will be here soon. Pete in Hyder Alaska We're all here 'cause we're not all there. |

||||

| Geoffg Guru Joined: 06/06/2011 Location: AustraliaPosts: 3194 |

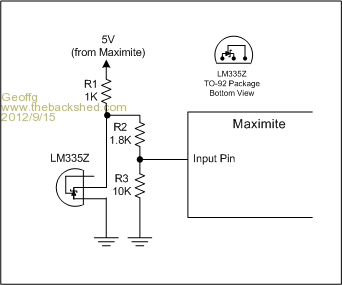

Nice to hear from you Peter. The LM335 has an output of 1mV per degree with zero volts at zero degrees Kelvin (ie, absolute zero). So, at 53 degrees C (which is 326 degrees Kelvin) the output of the LM335 is 3.26V which is the maximum that the PIC32 can measure with a power supply of 3.26V. This is why it stopped at about 53 degrees. When at a temperature of 100 degrees C the LM335 will have an output of 3.73V so you need to drop the voltage using a voltage divider so that it fits within the input range of the PIC32. I recommend using the following circuit:

Strictly speaking you should use precision (0.1%) resistors for R2 and R3 but a simpler method is to measure their value using a digital voltmeter and then substitute the measured values into the following formulae (which MMBasic will work out for you): Tmp = (((PIN(nn) * x.xx/3.3) / ((R2 + R3)/R3)) - 2.73) * 100

Where nn is the I/O pin that the sensor is connected to x.xx is the measured Vdd (3.26 in your case) R2 and R3 are the measured values of the resistors Tmp is the measured temperature in degrees C Sorry for the complicated answer but I hope that it helps. Geoff P.S, I don't envy your forthcoming winter. Geoff Graham - http://geoffg.net |

||||

pcaffalldavis Senior Member Joined: 17/10/2011 Location: United StatesPosts: 187 |

Thank you Geoff. I'll build that voltage divider into the components board. A little bit of copper foil board modification and a couple more resistors. Looks like a simple enough afternoon project. I probably just spent more time modifying the schematic and component board layout than the actual changes will take. That is good! It is all part of the learning curve and good plans will make building future boards even easier! Off to the post to get my last two 1" copper street elbows so I can connect up the water to air exchanger (like a truck radiator) and get this system running. I have a tank of hot water sitting out there from last nights fire so we can start getting heat in the house just as soon as the last two fittings are connected! Yahoo! This took a big part of one whole year from concept to realization. I've learning a bit more about electronics and my welding got better too! I feel a celebration coming on. There will be plenty of time this winter to tweak the program and make a bunch of option setting menus so anyone (like my wife) can adjust the settings without recoding the program. Good Lord, Isn't retirement fun! I never worked so hard. Pete in Hyder We're all here 'cause we're not all there. |

||||

| ronee Newbie Joined: 08/01/2012 Location: CanadaPosts: 20 |

Pete I see Geoff has answer your question nicely --- all I can add is, a thimble full of vegetable oil down the pipe will ensure good thermal contact with the chip Ron |

||||

pcaffalldavis Senior Member Joined: 17/10/2011 Location: United StatesPosts: 187 |

I must be one of the dimmer bulbs on the string. I built the voltage divider and it seems to be working. I have four temp circuits for LM335's on my component board. Three do not require a voltage divider and when the program is running without any sensors these three read between 3.79 and 3.82 volts. I'm assuming the small difference is in the 1.8K resistors. So on the fourth circuit now modified with a voltage divider as designed above by Geoff I now get a reading on that pin (4) of 3.27 volts. This is lower than 3.8 volts for sure and I'm guessing it will work. But was is puzzeling is when I attach a known working sensor LM335 to this circuit on Pin(4) I get negative numbers and when I heat the sensor the negative numbers get larger, go down, not up. I'm wondering if I entered the calculation formula incorrectly, or if there is maybe a bracket error in it somewhere? This MM on the bench reads 3.29678 volts at the four pins without any load so I am using 3.29 as the base voltage. The 1.8K resistor digitally reads 2.02 K ohms, the 10K resistor reads 9.85 K ohms. So here is my formula: BOILERTEMPCENT = (((Pin(4)*3.29/3.3)/((2020+9850)/9850))-2.73)*100 Am I missing something obvious to others? Pete in Hyder We're all here 'cause we're not all there. |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6098 |

Pete, One small change required: BOILERTEMPCENT = (((Pin(4)*3.29/3.3)*((2020+9850)/9850))-2.73)*100 That's a multiply instead of divide. I would use : BOILERTEMPCENT = Pin(4)*120.8 -273 and calibrate each sensor by changing the multiplier (120.8) for each Jim VK7JH MMedit MMBasic Help |

||||

| BobD Guru Joined: 07/12/2011 Location: AustraliaPosts: 935 |

If you read 3.27 volts on pin 4 then calculating by hand that would read about 120 degrees Celcius. That is very hot for water. Do you have a pressure vessel? To simplify your formula FOR YOUR SET OF RESISTORS only. (2020+9850)/9850 = 0.8298 so you can use that value in the formula and 3.29 / 3.30 = 0.9969 so close to 1 you can use that value (for the moment) Thus you get ((Pin4 volts / resistor ratio) - 2.73)*100 ((3.27/0.83)-2.73)*100=120.97 degrees C One minor (and irrelevant here) correction to GGs post above and that is the LM335 has an output voltage variation of 10mV / degree K. I suspect Geoff had a typo when he said 1mV / degree. The formula is still correct as presented but it threw me for a while as I couldn't reconcile why 100 instead of 1000 in the formula until I looked at the datasheet http://www.ti.com/product/lm335 In your program you should use the full formula as my simplification calculates a couple of degrees too high. Your formula (as shown) has correct brackets. I ran it through my editor which picks up such things. Not sure if I have helped you though. |

||||

| BobD Guru Joined: 07/12/2011 Location: AustraliaPosts: 935 |

I cocked up my calculations above. As Jim said is correct. I got the correct answer because I made a mistake in calculating (2020+9850)/9850 and inverted the answer to that but because I followed the original formula I got the correct answer. Your water is still very hot. |

||||

TassyJim Guru Joined: 07/08/2011 Location: AustraliaPosts: 6098 |

To check the maths At 60 degrees C the voltage at the LM335 should be 3.33V The voltage at the Maximite pin after the voltage divider should be 3.33 * 9850/(2020+9850) = 2.76 V BOILERTEMPCENT = Pin(4)*120.8 -273 =2.76*120.8 -273 =60.408 Jim VK7JH MMedit MMBasic Help |

||||

pcaffalldavis Senior Member Joined: 17/10/2011 Location: United StatesPosts: 187 |

That works! Yahoo. Thank you all! The voltages I reported for the four temperature sensors pins: 3.8 volts on the three regular sensors and 3.27 volts on the voltage divided pin, were all without any LM335s attached. Not actual temperature reading voltages. At room temperature the voltage divided LM335 pin reads 2.54 volts. I convert everything to F for my displays. And I just tested my 'high-temp' circuit on my tea and it went up to 159 degrees F. NICE It would not do that before. It's all a go! I will calibrate each circuit and use the simplified formulas. Thanks again! Pete in Hyder We're all here 'cause we're not all there. |

||||