|

|

Forum Index : Microcontroller and PC projects : Generic PIC32 mini board and MM "Shield"

| Author | Message | ||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

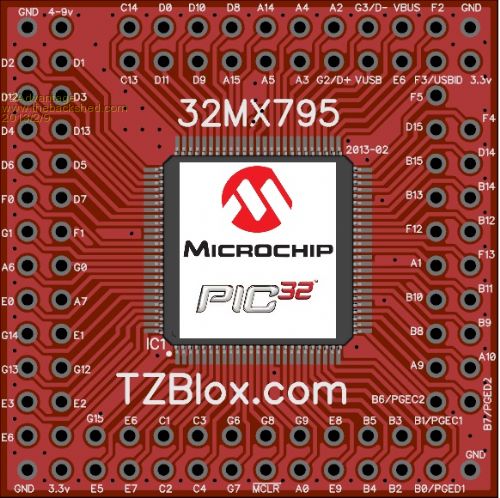

I changed the mcu card to something even smaller and simpler. It is now 37x37mm and has all the pins of the PIC32 available. To get this small parts are on both side. It can be made even smaller, like 27x27mm but then i have to use a 0.05" grid connector and that is not so easy to work with. As you normally would not do anything directly with the PIC chip itself you could choose to flip the print and have the voltage regulator, supervisory chip, caps and resistors on the top. If something has to be checked or measured it is probably one of those parts, and you still have all the pins of the PIC available on the connector pads. The result of this will be even a smaller print for a CMM clone leaving more space for connectors or your own circuitry in an enclosure. Tomorrow i'll continue to change the carrier board to accommodate this mcu board. here is the print front:

and back (or is it another front  ): ):

Microblocks. Build with logic. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

Oh Man Tz, khob khun krup, That is Beautiful... Unlike JohnS I prefer smaller, as the CPU part can be hidden inside existing equipment more easilly... but that is user preferrence and probably stems from me thinking of it more as a micro-CONTROLLER rather than a micro-COMPUTER, but the MM fills both genres beautifully... 27mm x 27mm whilst great size wise would need the .05" headers which are not out of the question... but maybe 37mm x 37mm is a good user manageable size. How are you thinking of marketing these? Bare PCBs or fully assembled or both? Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

Hi Mick, Thanks for that post. I would prefer to sell fully assembled and tested with or without headers. On request i could leave out parts, program the PIC and with volume it can be customized. I understand JohnS remarks. My solution for having more capabilities is actually to minimize the capabilities of a single 'Blox'. Combining them as you need them gives it flexibility and greater use. Extra 'Blox' or Carrierboards with or without prototype areas will add the functionality you need, as much as you want. With 'blox' you probably only need a single sided carrier board, which can be made at home. I was inspired by the UBW32, but felt that too much pins were used for leds and switches. Even on this small board i manage to give 2 pins a fixed function and i am already fixing that. Currently the pins that connect to the crystal are not available on the connector, predetermining that a crystal has to be used. But to be completely free even that should be optional. Only the decoupling caps are really necessary. I have some space left on the print and was thinking of having space reserved for a 32Khz crystal. Crystals have to be close to the pins and on the print itself is the only place you could add it without getting to much interference. I took great care to have ground planes to keep the signals as clean as possible. On a 2 layer board this is the best you can get. Caps and osc lines are as short as possible, i spread them a little to have the ground plane surround them for even better signal integrity. I might even put on an optional power led.

Could you think of something else to add as long as it does not interfere with pin usage. Microblocks. Build with logic. |

||||

| memberx Newbie Joined: 20/04/2012 Location: AustraliaPosts: 24 |

EasyPIC Fusion v7 ETH MCU Card with PIC32MX795F512L http://www.mikroe.com/easypic-fusion/mcu-cards/ MCU BOARD Plug in module PIC32MX795F512L 32bit USB MICROCHIP Microcontroller http://www.ebay.com/itm/MCU-BOARD-Plug-in-module-PIC32MX795F 512L-32bit-USB-MICROCHIP-Microcontroller-/181075468925?pt=LH _DefaultDomain_0&hash=item2a28f0627d How will your price compare for simple board? |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

Price will be comparable if not cheaper, volume will have a discount. I know these boards. The one from MikroE is good but does not have all the pins available, size is about 55x61mm. They have only the Ethernet version that is populated with a MX795 available, if you need more generic and all pins avilable you have to solder yourself and use the MCU card 1. Maybe they have a populated version but i not found it. If you need ethernet, MikroE is a good start as their compiler has good libraries for that. There experimenter boards are also good. The one on Ebay is from etteam and are leftovers because etteam does not have them in their catalog anymore. Not a good thing if you need a good supply. And the biggest problem, they don't have a crystal! That makes it unsuitable for timing critical uses like serial communication or or timing uses. etteam shop is about 2km from my house and i visit them regularly. I have bought these boards before and they are of good quality. They also have some pins reserved, or pulled up making them unusable for other purposes. Microchip also has a board, the MA320003 about 30US$. They are however now in their 'legacy' part of the catalog suggesting that they will just sell stock. Their experimenter boards now use different connectors. They all are for experimenting/learning purposes and not offer much practical use for end products. For that you need to have short as possible traces and lots of ground planes. For that the one from MikroE comes close. I considered making a 4 layer pcb, and i still might do that for even more shielding. Costs are however much higher to produce. The problem i had though with the current available modules (and that is the whole reason i started with 'Blox' is that once you have something ready you have to transfer it to something that you can use. You than have to very carefully replicate what is on the mcu module and experimenter board. Dimension your power supply, match components, check interference, placement etc. I much prefer to use exactly the same parts for prototyping and final product. Just replace the wires with pcb traces. Not much can go wrong then. Keep in mind thought that the one i designed still has to go to manufacture and test. That will take at least 5-8 weeks depending on manufactoring, transport etc. If interest is high though and time short i could speed it up and order some pcbs more quickly. Costs will be much higher though, around 25US$ for a bare pcb. Microblocks. Build with logic. |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

I have added a 32Khz crystal with caps and 2 power indicator leds on the 3.3v line. I added to more pins to the connector making the pins that are normally used for the main crystal accessible. They only are available when no crystal is in place and the PIC is using its internal resonator. The choice can be made to close 2 small solder bridges. On the picture on the left bottom.

On the back (or alternative front) i moved the power regulator to make room for the 32KHz crystal. The wire length to the osc pins are very short and are also surrounded by ground planes. Same procedure when this crystal is not used, solder the 2 bridges and those pins are available on the connector.

I think i am very close to send this one to the pcb manufacturer. I am waiting for a few parts to arrive so i can do the final measurements. Would not want to find out that some parts not fit. Remarks and tips are welcome, and if i miss something essential, now would be a good time to warn me.

Microblocks. Build with logic. |

||||

donmck Guru Joined: 09/06/2011 Location: AustraliaPosts: 1313 |

is this the sort of thing you are looking for? http://www.dontronics-shop.com/olimex-duinomite-io-board.htm l This is set up as mono. Don't know if it can be easily reconfigured for colour, as you will require a few more connector pins. schematic at: https://www.olimex.com/Products/Duino/Duinomite/DUINOMITE-IO /resources/DUINOMITE-IO-REV-B.pdf Don... https://www.dontronics.com |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

I am more looking to have connectors stacked. Next to each other demands a lot of room. If i can not find those then something like your example is a good alternative. At least you are then more flexible where you put the connectors. Together with a back plate it will be strong enough, and only a short cable to plug it on the main board. I am not too scared of manual labour as that is pretty affordable in Thailand. So soldering a few wires on connectors is not a problem. I would like to avoid mechanical stress on a main pcb especially for the VGA, keyboard and sound. The stronger the better. Microblocks. Build with logic. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

TZ, 5-8 weeks seems a long time to get them produced, my experience with the PCB manufacture is typically around 10 days from submit order till boards arrive. A cost of $25 per bare PCB is way over the top, I doubt that you could sell any at that price, especially if you want to add some profit margin. Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

TZ, Can you squeeze in a programming header? I dont think you can with 0.1" spacing but a .05" header similar to the Olimex DM range might be workable. Regards, Mick Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

Hi Mick, 5-8 weeks is including testing and optimizing components. And i would like to panelise with some other small boards to optimize costs. If i really want to rush and get a board in 1-2 days then the price goes up a lot, tooling costs are the main problem. I just mentioned it if someone really wants one now. Once the first boards are checked and manufactured the unit price goes down a lot. I guess you already know that, but i just explain for others. I tried to put on a programming header but i just don't have the room for it. It might be possible with a surface mounted one, but then i really don't like surface mounted parts that can have forces on them. It was actually one of those difficult decisions, small size or bigger with more features. Small size won this time.The module is meant to be used with female headers, so plugging in a few wires would not be that big of a problem. Maybe i make a small pcb that plugs into those connectors and have the ICSP header together with some jumpers to select which of the two available programming pin combinations you like to use. The carrier board for the CMM will have a programming header and USB, so in practice there will be options to easily program it. Microblocks. Build with logic. |

||||

| paceman Guru Joined: 07/10/2011 Location: AustraliaPosts: 1329 |

Would it be better to replace the LED with pads for an optional 3mm LED - that way it could be mounted on the board or to the box if preferred so that it can be seen. Greg |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

Paceman, It is just a resistor and a led between the 3.3v and the ground. It is not of much use in an enclosure, but when used as a companion next to a breadboard it is nice to have a visible confirmation that the 'Blox' is having power. Microblocks. Build with logic. |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

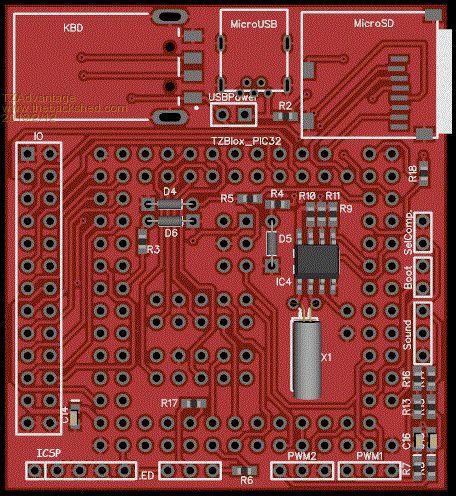

Time for an update. After a 16 hour session drawing schematics, and traces here is the result so far. It is a Color Maximite clone, only the Arduino connector is dropped and replaced by headers. I have choosen to use a VGA header use a DSUB that can be mounted in an enclosure. This will prevent stress on the pcb and more important saves a lot of room. The same for the sound connector. Some might want it in the front, or build a small amplifier, or headphone connector. The choice is yours. I have also included 2 joystick ports. I used my own pinout, as the PINS are still available on the IO connector a joystick as before can also be used. It is all a software decision. The joystick connectors have 5 digital inputs and 2 analog. They can be used for other things then joysticks. It is an easy way to break out some of those extra pins. I added some headers to have direct access to the PWM pins. The R/C used for sound is then not connected. This can be good for controlling servos, or backlights of LCDs. The realtime chip has a pin that pulses. It is available on a header and it canbe used for timing purposes, or just blink something. :) The keyboard connector is a USB type A, it is wired as a USB to PS/2 adapter. Also a Micro USB and a Micro SD is on the board. A battery for the RTC might fit next to the chip. Have to try it out. (I forgot the markings for the Bat connector on the front.) Here are the pictures. And the surprise will be its size! Front:

Back:

Ok, the surprise is, it is 50x55mm! Now i go sleep. :) Tomorrow i'll add a power regulator, reset header and a programming header and some stitching to connect the ground planes.. Still thinking about the ICSP header, because as a CMM programming will be done via USB and the PIC32 plugin board has easy access to the programming pins and i have never used the ICSP on my maximite before. Microblocks. Build with logic. |

||||

bigmik Guru Joined: 20/06/2011 Location: AustraliaPosts: 2914 |

Hi TZ, I like... No I love what you have come up with, The size is amazing... however when the CPU board is plugged in how do you propose to gain access to the high order (ie. Pin(21)-Pin(40) group? I agree with your idea of a USB-A header.. and who know in the future it might be possible to actually us a USB only k/b there if the k/b code can be modified for USB.. There is still room for Program header, which in my opinion needs to be there. See bottom left of this overlay for a mockup.

Regards, Mick EDIT*** wrong image uploaded ... sorry Mik Mick's uMite Stuff can be found >>> HERE (Kindly hosted by Dontronics) <<< |

||||

MicroBlocks Guru Joined: 12/05/2012 Location: ThailandPosts: 2209 |

Hi Mick, In that corner i would like to put a voltage regulator and another cap. The PIC32 pins for programming are on the opposite site, where the USB-A connector is. Running traces from there for the ICSP will make it impossible to have traces going to the PIN1-PIN20 connector. Only way to do it is to make the print bigger or 4 layer. Both not as desirable. The size has a reason and that is that i want to stay withing certain boundaries. Those boundaries have to do with a set of enclosures i am also designing. Another, i think, good reason is that the ICSP is more a PIC32 specific thing then it is for the CMM. The CMM can be updated through USB and that is practically what everybody uses. The only time ICSP is used is when uploading a boot image, or when you want to do some programming in C and want to debug. In that case it is important you can choose which set of programming pins to use or maybe you want to use JTAG. I would like to keep that decision open so anyone can choose their favorite. I have all of that in schematic design ready on a small adapter that plugs into the PIC32 board. I will show a picture later. It is hard to see from only the pcb layouts but i try to describe how it will look like. If you have the CMM carrierboard you would place female headers to accept the PIC32 board. The PIC32 board also has female headers but ones that have longer leads, the same as are popular with the Arduinos. When you plug that in you have access to all the PIC32 pins in a layout very close to the chip's. You can then even stack another board on top of it. It is even small enough to fit inside a slightly modified Atari joystick.

Another possible enclosure is like an XBox controller, together with the chat keypad. Even another is a small case with an LCD, like the nintendo gameboy. Size matters! When developing your own project you can then choose which connection is most convenient. The PIN1-20 on the 26 pin connector (Back), PIN 21-40 on the IO header and Joysticks connector (Bottom), or the ones from the PIC32 board (Top). Lots of freedom when you want to add your own circuitry in the same enclosure. When you use it as a BASIC and Game computer you have all you need and the enclosure will hold the connectors for everything, making it child proof. I guess 2 joystick ports on the left and right, USB on the right, VGA and sound on the back. SD card and LED on the front. A reset switch and bootloader switch on the back. Still to do is having separate headers for the reset, I2C and CAN. Microblocks. Build with logic. |

||||