|

|

Forum Index : EV's : Electric farm bike

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

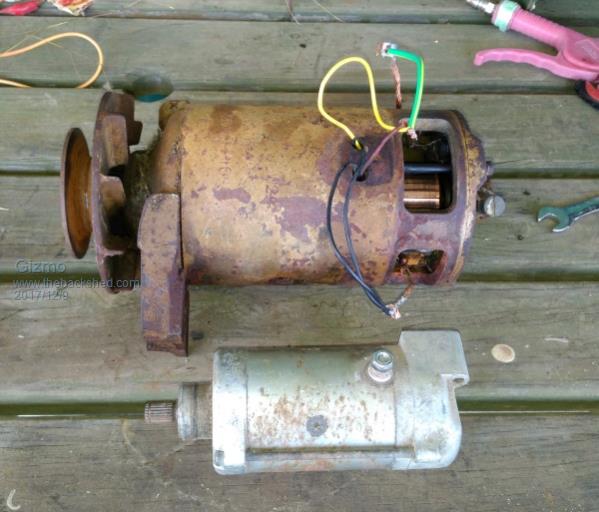

Playing around with the idea of building a electric bike for scooting around the property. I have "mini-bike" with fat tyres and a 50cc 2 stroke motor thats a b%$#t to start and has a slipping clutch. So the thought was fit a electric motor. I have a 12v battery in reasonable condition, so I want to use a 12v system. The bike will be used for short quick drives, like 200 meters or so at a running speed. I have a little starter motor from a 350cc motor bike, its a DC series motor. Maybe a little on the small side, but it does at least have ball bearings, most starter motors only have bronze bushes. I also have a big old 12v generator. The generator has a ball bearing at one end, bush at the other. Its large and rugged and its thermal mass should help keep it cool, if used as a motor.  The generator's 2 field windings were wound with what looks like 1mm wire, and the two fields were connected in series, giving a resistance of around 7 ohms. The armature looks a lot heavier, with a resistance of about .3 ohms. To get power I'm going to need current, and 7 ohms in series with the armature is not going to work well, so I wired the motor in a shunt configuration. I wired the 2 fields in parallel, giving about 1.8 ohms, then connected this in parallel with the armature. I locked the armature using a foot long lever and scales, and connected a 12v battery. The armature alone draws about 52 amps, the windings 6 amps give or take. I was reading 2.5 foot pounds at 58 amps.  I then tested the little started motor, it was about the same foot pound figure and similar current. So I'm undecided on which motor to use. Ideally I should rewind the fields using heavier wire, and then connect the motor back to a series configuration. I have lots of 2mm wire. But I'm not really sure. Any suggestions? Then I also need to consider control. Maybe something simple, couple of contactors and a big resistor. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1020 |

We used them old generators to run our 7 1/4 gauge model trains/trams, we ran them on 24v and they still used about 40amp. they will reach a certain speed and thats about it, the fields were holding it from revving any faster until we dropped the field voltage to about 12v and left the rest alone then she took off, but not much power. (I think it was the fields? it was along time ago). The speed control beforehand was just a set of relays and resistors, (Heavy Nichrome wire) I don't think that it is worth rewinding it, a lot of work not much gain. Will see if I can get a photo of the speed control. Cheers Aaron Cheers Aaron Off The Grid |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1020 |

The speed control was just a rotary switch that turned on the small relay's one at a time. The small relay's turn on the large relay's (Ex telecom exchange) with decent size copper contacts, each one will run the motor through a separate resistor for 3 speed a the fourth relay just runs the motor direct. Its pretty old now but at the time it run well and never give any trouble, if I power it up again it will still work after all these years. There are many other ways of doing this but if you are making something out of the gear you have sitting around the place, it works. I had an idea some time ago about building an electric bike for around the farm, it would need to run for at least 3Km to be worth it, I thought about using a washing machine motor F/P or something like the LG washing machine has, at 800rpm it was using around 100 watts, would need rewiring if possible and would be nice if it could be bolted directly to the wheel. I don't have any to play with so I have know idea if it would work that way. Cheers Aaron Cheers Aaron Off The Grid |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thanks for the info Aaron. Those photos will be helpful if I go for a contactor/resistor type of controller. I discovered a started motor from a Landrover 3.5l V8 in my collection of junk, its big and heavy, might have too much power for the farm bike, but i'll test it out later today once I wipe all the oil off it  Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| isochronic Guru Joined: 21/01/2012 Location: AustraliaPosts: 689 |

The AEVA in victoria used to have races with the carts mainly using old generators OK. Not off-road though. The fan is required I think ! |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

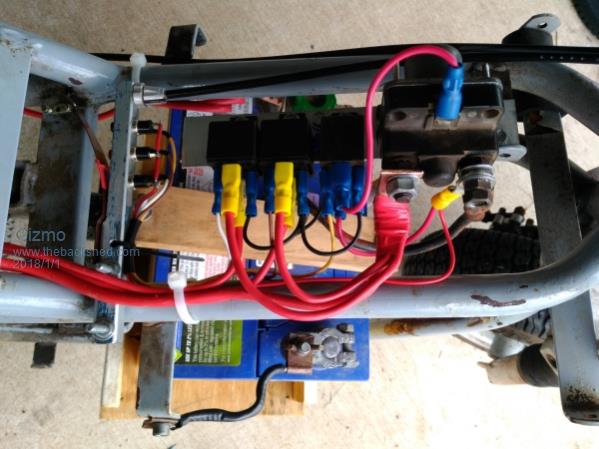

Well the bike turned into a nice Christmas holiday project, was good to spend time in the shed instead of at the computer. Worried the starter motor from the Landrover V8 was too big, I ended up scoring a couple of starter motors from old Mini's. These Mini starter motors have the advantage of the drive shaft extending out of the motor the housing. I cut off the bendix drive and mated the motor to a gear box from a old 9 inch angle grinder. This then drives the back wheel via a chain and sprockets from a long dead electric scoota. The chain is very light, but hasnt broken yet, we'll see how it lasts. The gear box and chain give a ratio of 24:1. Back wheel diameter is 330mm.  Rigged up a battery, push switch and solenoid, first test run. Lots of torque, wants to lift front wheel. Top speed is a jogging speed up my driveway ( about 20:1 inclination ). Down the driveway was too fast for my liking, Mini bikes are not stable!  I needed some sort of speed control, or at least a soft start circuit. Found 16 70 amp MOSFETS on a heat sink, and used a PWM drive from a 12v electric drill to drive them. It worked, nice control of the motor speed, then one MOSFET went short circuit. MOSFETs, inductive loads and big current is black magic, I decided to stay away from that voodoo and keep is simple. Resistors and relays. I made a simple 3 stage throttle control. It uses the cable drive from the hand control to pull a spring steel strip onto 3 push button switches. These control 3 relays.    The first two relays feed battery power through two wire wound resistors. The last relay drives the big solenoid. If I lock the motor, the power steps up at 50, 120, 150 amps as I rotate the hand throttle. Once moving, the current is about half. The two relays feeding the resistors are only rated for 30 amps, so good chance they will fail. The bike has been for a couple of drives up to the letter box and back ( about 150m up the drive way ), and battery indicated full change at the end. I've also used it to take the full wheelie bin up to the road, no effort. Just a matter of waiting for something to break and replace it with a stronger part. I have a 10 watt solar panel and charge controller, will use these to keep the battery charged. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1020 |

Thats looking good Glenn  I remember burning out a few of those relays, but it proves how it works, they will drive larger relays, or there may be other stronger SSR types around. All good though, its nice when something comes together and just works.  Cheers Aaron Cheers Aaron Off The Grid |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9303 |

I agree - it looks great, and I particularly love your use of an old angle-grinder gearbox! I will have to remember that one for my own hacks now!  Something to bear in mind though, is that those M35 starter motors and the starter solenoid are designed for intermittent use only. IE: Cranking the engine over for a few seconds. Running the motor continuously(especially at full speed) will probably kill it quite quickly, but then, you never know!  The starter solenoid is most definitely designed for only intermittent use, so if that is acting as your main switch to the motor(which I expect it is), then you will probably burn-out the coil on the solenoid rather quickly. Those solenoids are quite good at failing even when used intermittently as designed!  I have classic Mini's, 1100/1300's etc(yes, I am a sick boy), so am well familiar with solenoid and starter motor replacement. (solenoid is the most common to fail out of the two) Smoke makes things work. When the smoke gets out, it stops! |

||||

| Boppa Guru Joined: 08/11/2016 Location: AustraliaPosts: 814 |

You can get a solenoid rated for 100% duty cycle as well- repco stocks em as well as heavier than 30a relays (from memory they had 80a relays as well as the 200a solenoids) I used the 100% one for battery charging in the old hilux- its approaching 10yrs with no issues, on whenever the engine is running... |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thanks for the feedback. I think the starter motor will be OK. After a typical trip its warm to touch, but not uncomfortable warm. But I'll keep an eye on it, might fit a fan to blow air through it if I think it will help. But yeah Grogster, the starter solenoid draws 5 amps! It does get uncomfortable warm, and its a waste of current. Boppa I ordered a 200 amp relay off ebay. I've seen them for under $10, but I ordered one for $18, it had quicker delivery. If it turns out OK, I'll order a few more and replace all the 30 amp relays. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9303 |

@ Boppa - Yes, you are quite right.  You CAN get 100% duty cycle solenoids, and that's what is needed. My point being that the Lucas starter solenoid from all the classic Mini's, Austin or Morris 1100/1300, Reiley Elf, Woolsley, and Allegro are all intermittent type. I listed all those models, cos it is relevant. The same solenoid is used in a whole plethora of British cars of the day, so they are the ones you are gonna find 99% of the time. You CAN get 100% duty cycle solenoids, and that's what is needed. My point being that the Lucas starter solenoid from all the classic Mini's, Austin or Morris 1100/1300, Reiley Elf, Woolsley, and Allegro are all intermittent type. I listed all those models, cos it is relevant. The same solenoid is used in a whole plethora of British cars of the day, so they are the ones you are gonna find 99% of the time.  But I hear you on the better solenoids, and that is the way to go. But I hear you on the better solenoids, and that is the way to go.@ Gizmo - Motor: Okey dokey.  I guess the load of pushing a wee bike around is nothing on cranking over a cold engine, so they might well last longer then I am suggesting. Hell! You don't know for sure unless you try it, and you are doing that for us! I guess the load of pushing a wee bike around is nothing on cranking over a cold engine, so they might well last longer then I am suggesting. Hell! You don't know for sure unless you try it, and you are doing that for us!  If your one survives, I have a stack of M35 motors - I might make something similar myself! Yes, the standard Lucas solenoid usually draws about 5 amps as you have found, and some I have seen draw upwards of 7.5 amps. USUALLY not a problem for intermittent use, cos the solenoid is only drawing those amps while you are trying to start the engine. In your application......I wish you the best of luck, but I expect that solenoid to give up and die from heat stress sooner rather then later. If your one survives, I have a stack of M35 motors - I might make something similar myself! Yes, the standard Lucas solenoid usually draws about 5 amps as you have found, and some I have seen draw upwards of 7.5 amps. USUALLY not a problem for intermittent use, cos the solenoid is only drawing those amps while you are trying to start the engine. In your application......I wish you the best of luck, but I expect that solenoid to give up and die from heat stress sooner rather then later.  I will be very interested to see how you get on with your 200A relay. I would be inclined to half it's rating(you know eBay sellers!), but I fully expect it would be perfectly happy with the motor current of your bike, as I doubt that is even 100 amps full-tick. I will be very interested to see how you get on with your 200A relay. I would be inclined to half it's rating(you know eBay sellers!), but I fully expect it would be perfectly happy with the motor current of your bike, as I doubt that is even 100 amps full-tick.Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

This is the relay I ordered. https://www.ebay.com.au/itm/292326076852 If its OK I'll order a few. I have two of the Mini starters, the one I'm using is totally enclosed, but the other one has a different brush set up and has open sides, similar to the picture of the generator above. I'm not sure on the power ratings of the two different types, but, the open design means I could fit a 12v fan to blow air through the motor, might help extend its life. Using the gear box will help bush life, there is minimal side load on the armature shaft and bushes. It feels like the motor has a torque band / RPM that it seams to be happiest at. Yesterday I used it to take another full wheelie bin up to the road ( bin day today ), and it goes up the hill at the same speed with the bin as without. I'm tempted to play around with gear ratio's to see how fast it will go, and still tow a wheelie bin up the hill. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Boppa Guru Joined: 08/11/2016 Location: AustraliaPosts: 814 |

It would be worthwhilke if you havent already done it, to give the motor a service (lube and com cleaning), reoil any bushes etc They are hard to find these days but the old car gennys made great motors, I have seen many pressed into service on ride on model railway locos etc |

||||

Grogster Admin Group Joined: 31/12/2012 Location: New ZealandPosts: 9303 |

You mean the C40 generators? They were a great unit. I heard that they used a boxful of those as wind generators down Stuart Island way. They just hooked the wind blades to the genny motor shaft, and used the genny and RB340 voltage/current regulator exactly how it would have been used in the car. That then charged up the battery banks. Very little hacking required, other then pulling off the V-belt pully and fitting some propeller blades! .....but I digress - sorry Gizmo.  Smoke makes things work. When the smoke gets out, it stops! |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Feel free to digress, all good info. The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Here is another angle grinder gearbox hack: Making my own PCB's occasionally I always found that copper/ fiberglass is hell on saw teeth if one uses them for cutting it. I do not have a XY router so...   Powering it with the portable drill gives another job for that besides the 1mm cutting disk rotates at just a nice speed rather than the scream and smoke the original angle grinder motor would give this saw. Klaus |

||||

| Boppa Guru Joined: 08/11/2016 Location: AustraliaPosts: 814 |

hmmm thinks of all the dead grinders Ive chucked out over the years... Love the pcb cutter- I use a sheet metal guillotine for pcbs, altho it isnt good on anything smaller than a few cm as it tends to crack them looks like I'll have to find a dead grinder.... |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1020 |

I wish those relays were around when we did that other project 20years ago, think I will get a few of them next time.  Another option we used to use on the model railway locos was the Right Angle Drive from an Outboard leg, larger ones had forward and reverse, very strong but usually they are 1:1 gearing. Cheers Aaron Cheers Aaron Off The Grid |

||||