|

|

Forum Index : Other Stuff : Do you need to cut splines for your F&P?

| Author | Message | ||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

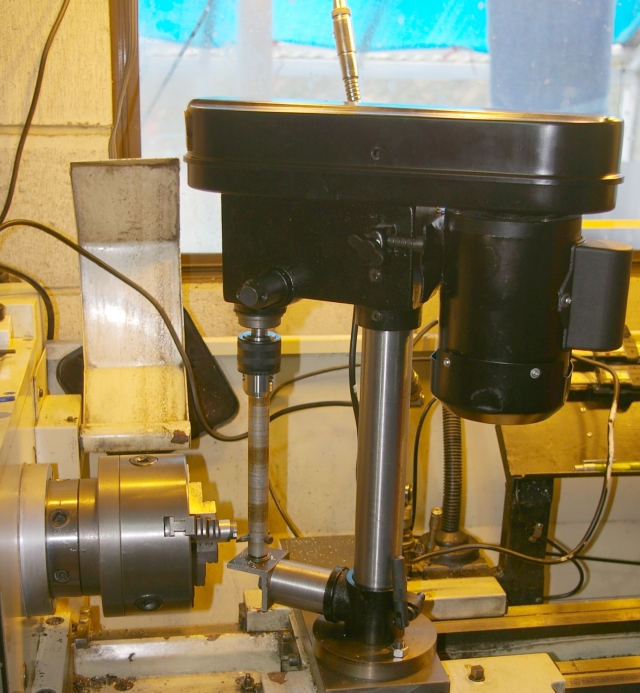

$20 slotter and maybe spline cutter! This little chinese drill press was too cheap to ignore at about $20 and it has been resting it its box while I decided what it might be useful for. First step, mount it on the cross slide of my 12x36 lathe.

The orginal base has been replaced by a turned plate and a support fashioned to hold a ball bearing in line with the spindle of the drill.

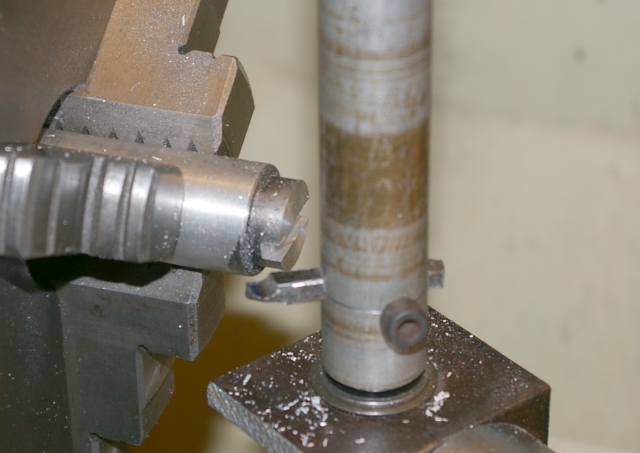

A spindle is mounted in the chuck with the other end in the bearing. A simple cross drilling and a set screw form a simple tool holder for 6mm tool steel. As you can see it cuts a nice slot in the end of this piece.

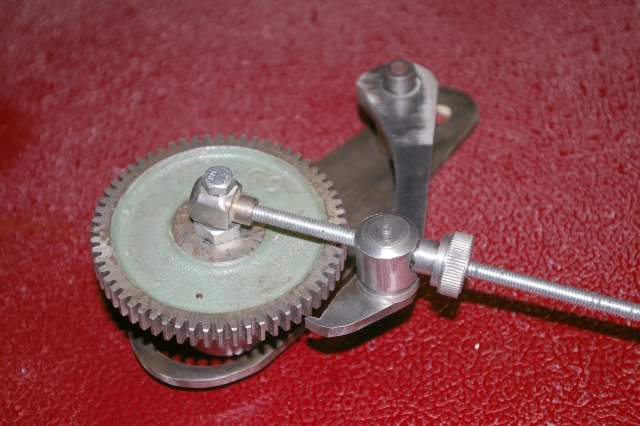

The next step is to make an indexer for the lathe spindle and fortunately I have a set of Hercus lathe change gears on hand that can be pressed into service. The change gears are not Chinese but they do appear to be of adequate quality. |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

{A couple of days later!} I have made an indexer to go with the vertical spindle:- I made a pile of bits...

...which put together look like this..

...the aluminium bit screws into the end of the spindle and the small hole goes over the stud that secures the gear case cover..

One detail which you cannot see is that I added a nut on the gear cover stud inside so that the knurled knob has something secure to screw down on to, not just the springy fibreglass cover. |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

G'day John, It may pay to look for a set of dividing plate wheels as used on dividing heads and rotary tables. Mount the plate rigidly on the rear of the headstock. When I have needed to do similiar in the past I did find it was very handy as the headstock needs to be held rigid or forget cutting straight as the headstock will turn. Need to cut a spline where there isn't any holes circles to suit, just turn that light bulb on between ya ears and make one that works using the original plates. Cheers Bryan |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Hi Bryan I have made a few test cuts and kept my foot on the spindle brake while cutting, it is not ideal as there is a little backlash between the spindle and whatever the brake is on. I have not figured it out yet but a brake on the spindle nose would be better. Cheers John |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Hi John Nice work mate , good to see you are making the most of your lathe . Where have you been havn't seen you here for a while , it looks like you have been up to a few projects . PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Hi Phill Yes, I have been having a lot of playtime with the lathe! I have been around lurking a little but not saying much as much of the forum has sort of moved ahead of where I am at, we are living town and although there is plenty of wind there is not much scope for windmill development! cheers John |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi John I like your dividing method very positive and functional. All the best Bob Foolin Around |

||||

MacGyver Guru Joined: 12/05/2009 Location: United StatesPosts: 1329 |

KiwiJohn Hey! That's really neat. My lathe is very tiny ( 3 1/2" swing!) and I run it off a 12-volt garden tractor battery. I've been wondering how to make a milling attachment and you've just shown me how; thanks! Every now and then I have to mill a slot in something and up to now, I've just done it other ways. If I actually find time to build one like you've done, I'll post pictures on the 4m. Right now, I'm in the middle of an axial-flux windmill build, but when that's done, maybe I'll have time to tackle this project. Thanks again for the great idea and post. NIce work! . . . . . Mac Nothing difficult is ever easy! Perhaps better stated in the words of Morgan Freeman, "Where there is no struggle, there is no progress!" Copeville, Texas |

||||

| matt down south Regular Member Joined: 20/10/2007 Location: AustraliaPosts: 50 |

nice work Kiwi John,a doable setup we can all copy,thinking outside the square is a good thing,well done  matt |

||||

| KarlJ Guru Joined: 19/05/2008 Location: AustraliaPosts: 1178 |

indeed I like it Luck favours the well prepared |

||||

| matt down south Regular Member Joined: 20/10/2007 Location: AustraliaPosts: 50 |

i do a hobby/homer fitting and turning corse at tafe and when i ran it through the teacher that is a very clever man he to thought it was a good idea so well done again kiwi john  matt |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Thanks for the comments!  |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Nice idea, and good to see you here again John. I'm a bit lazy, and for keyways etc, I just use an endmill in the chuck, and the workpiece in the toolpost, and use the cross slide to push it past the endmill... but this is a nice and different way of doing things, ...... and I like options..... a lot. Keep well. ............oztules Village idiot...or... just another hack out of his depth |

||||

| KiwiJohn Guru Joined: 01/12/2005 Location: New ZealandPosts: 691 |

Months later... I did manage to cut an aluminium gear, 60T, on another rig, which I have incorporated into the latest development of the slotter:-

The drill is geared down 28:60 which gives speeds between about 200 and 1000 RPM. I find the single point 1.5mm wide cutting tool runs best at the high speed but I assume I will need the lower speeds if I ever get to mount a bigger diameter tool of any kind on the. Reversing the rotation makes it much easier to see the work and allows cutting towards the chuck without 'climb milling'. The idea for making this change was to move the cutter spindle closer to the drill column to gain more rigidity, it seems to have worked and the tool cuts nice slots in steel without any difficulty. One mistake though, I should have made an acetal gear as the aluminium one is rather noisy!  |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Nice work John. Yeah the straight cut aluminium gears do make a lot of noise. I remembers my brothers Monaro ( its a family thing, we've both had 350cu Monaro's ), he fitted straight cut aluminium timing gears. What a noise, very loud whining. Sounds cool, but you get sick of it. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||