|

|

Forum Index : Other Stuff : Portable Battery Charger

| Author | Message | ||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

I'm putting a page together about portable chargers, you know, the good old car alternator bolted to a small petrol motor.

Mine is a 75Amp alternator bolted to a 5hp motor, mounted on a trolly. Its got me out of trouble a few times with flat car batteries. In the article I talk about reversing the fan, adding a amp meter, and a few other small details. What I would like help with is some photos of other builds. If you have a photo of your own portable charger, post you picture here and I'll add them to the page. I dont care how ugly or pretty it looks, its just to give others ideas on building their own. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

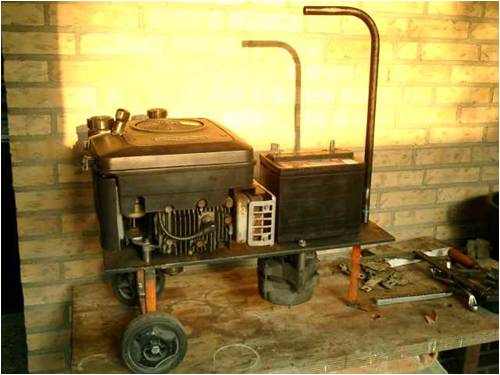

Only picture I have of it in its 'nearly-finished' state. This configuration was chosen to be able to run the alternator normally, with proper cooling (fan turning in the correct direction). Seemed the simplest solution to me to me to solve that problem this way. Wheels and a handlebar complete the portability. Images below shows test fitting the alternator and engine. There's a curved slot in the 8mm steel mounting plate to be able to tension the belt by varying place of the alternator.

Used the mark-8 controller, as published in Homepower magazine. Useless controller. Didn't control properly and developed a lot of waste heat (in the transistor). Would use a few switched lightbulbs to control field if I were to do it again. Next time I wouldn't bother to build such a genset anymore. Was a useless project for me and has been thrown away a few months ago in the most recent move. Was fun to build though and helped me out on one particular occasion with troubleshooting the instrument panel of a boat (they didn't install a diode in a crucial place in that panel. This stand-alone motor/alternator combo made troubleshooting that instrument panel a piece of cake. Much nicer to work at leisure at home in the workshop/patio than out in the field in a hot, humid and cramped engine room standing in bilge water). But was noisy (engine running at ~3000 RPM). Ron was right - petrol engines suck, diesels rule. Alternator was a 55A Delco-Remy one, with internal electronics removed (apart from the rectifiers). Now toying with the idea of taking a small car diesel motor and coupling it to one of the motor conversions. A few kW of 3-phase backup-power (230 Vac and 400 Vac) would be nice. Bit similar to what RossW has built. Of course one or two car alternators would be bolted on to it as well. Engine shouldn't even notice the extra load. But probably much easier/quicker/cheaper to buy a used diesel genset. Can't help but ponder a Lister/Petter/clone coupled to one of the conversions too. Quiet, slow and diesel. Then again, those lawnmower engines and alternators are plentiful and can be found for free. What's wisdom.... Peter. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Thanks for the photo's and info Peter. I've been looking for a small diesel motor, something that could be run on bio-diesel, but they are hard to find. I have a collection of small horizontal shaft stationary petrol motors, a couple are pretty old, all fun to work with. The latest was picked up for 5 dollars, it wouldn't start and had no compression. I ripped the head off, and as I suspected the exhaust valve was stuck open. A spray of WD40 and gentle tap with a hammer fixed it, bolted the head back down and it fired up on the first yank. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

I built a similar setup to Dinges using a 3.5HP briggs vertical shaft. I found it very hard to start because it needs the blade cutting disk as a flywheel. I machined the end off a car axle and added it as a flywheel and that worked. A cutting disk without blades would have been easy if I had it. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

I've put the page up... http://www.thebackshed.com/Windmill/articles/PortableCharger .asp I've included Dinges photo and added Robbs comment about the flywheel. Let me know what you think. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| readyakira Senior Member Joined: 17/07/2008 Location: United StatesPosts: 114 |

I'm going to start this project before I go any further with my windmill one since I have alot of material on hand. I hava an old MTD lawn tractor with an 18.5 hp twin cyl brigs and stratton on it. The deck and steering are rough so this should make a good genny cart and engine. I have a few alternators sittinbg around to use, and plenty of bedframes for angle iron. I just need time and maybe some pulleys... Does anyone know where I Can get some pulley info, like ratios and how can I easily tach the briggs toi know it's RPM? Don't you think Free/Renewable energy should be mandatory in new buildings? |

||||

| Greenbelt Guru Joined: 11/01/2009 Location: United StatesPosts: 566 |

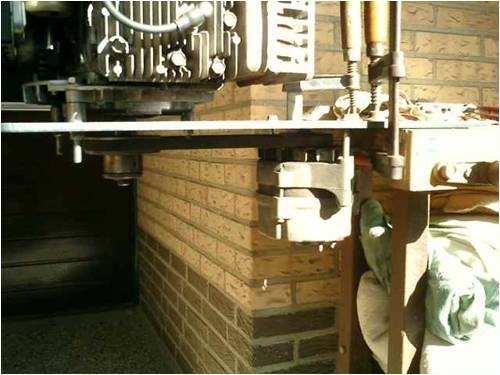

Glen; You mentioned Ugly. Might as well pin the blue ribbon on this.!!

Time has proven that I am blind to the Obvious, some of the above may be True? |

||||

| Robb Senior Member Joined: 01/08/2007 Location: AustraliaPosts: 221 |

One rather different way of measuring RPM I'v used is to record audio on the computer with a program that draws a wave graph and count the waveform over a given time. Audacity could be worth a look. |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Good tip Robb, makes sense. Thats a interesting photo Greenbelt, the starter is a good idea. Luckily my motor starts easily, first pull of the cord usually. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| readyakira Senior Member Joined: 17/07/2008 Location: United StatesPosts: 114 |

I am probably going to look into on e of those rather cheap tach tools from harbour freight like this one: http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnu mber=66632 I can see there being quite a few concerns with the audio method. for example my compressor is twin cylinder so the frequency would be double actual rpm. On a F&P the noise created I am sure doesn't coincide to one revolution, and would be different with different wiring schemes. Don't you think Free/Renewable energy should be mandatory in new buildings? |

||||