|

|

Forum Index : Other Stuff : refrigerator insulation

| Page 1 of 2 |

|||||

| Author | Message | ||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

I've been toying with the idea of adding extra insulation to the refrigerator to reduce energy use. I know this project is by no means original, plenty of people have done this, but I've never seen anyone actually measure how much less energy the thus modified fridge uses. For the past few months I had been eyeing the old refrigerator (Bauknecht) suspiciously, as it seemed to be running a lot of the time. Then, during the summer, I noticed it actually never turned off anymore: everytime I passed by it it was running. That couldn't be good, as it used 95W when on, so about 2.3 kWh/day... or about 185 Euro per year... Ouch. So it was time to go shopping for another fridge. Here she is, the new Zanussi ZRG616WS, in factory condition:

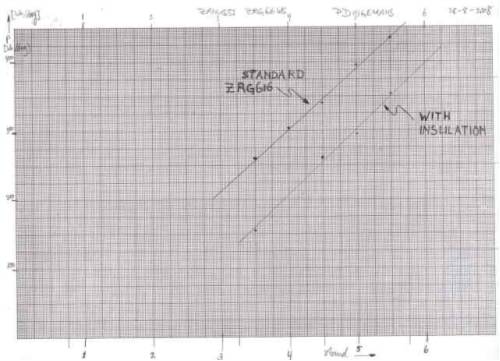

Only 152 liter (5.5 cubic feet) but large enough for me. No freezer compartment as I don't need it; have a separate freezer for that. The manufacturer states that it uses 151 kWh/yr, i.e. .41 kWh/day. Compare that to the 2.3 kWh/day that the old fridge needed. The fridge cost 180 E (including 17 E removal tax, err, 'contribution') and as electricity over here costs .22 E/kWh, break-even point is at 14 months. This is assuming that we don't soon get another electricity rate increase of 27%, as we did last July... Now, 410 Wh/day isn't too bad as-is, yet it can always be made better... But first I decided to make a few measurements using the kiloWatthour-meter before embarking on the insulation project. For a few weeks I measured electricity consumption at various thermostat settings. The results of the measurements are in the graph further below. At 5 deg. C (setting '4' on the thermostat) the fridge uses 304 Wh/day, quite a bit less than the manufacturer's stated energy usage of 410 Wh/day. That's the first good news: the fridge uses 25% less energy than stated. Ok, now that we have a baseline for comparison it's insulation time. First thing added was a radiant barrier between the fridge cabinet and condensor coil, to radiate the heat from the condensor away from the cabinet. Same with the compressor compartment, where more radiant heat barrier was added:

Then, as I took the top cover of the fridge off I noticed this was completely empty, apart from a small styrofoam spacer. This is 23 mm of space that the manufacturer could have easily filled with some insulation. Amazing. Even plain styrofoam (with a thermal conductivity of 0.038 W/m.K, which is mediocre as far as insulation goes) would have been better than absolutely nothing.

So I took a sheet of 30 mm styrofoam and cut it to a thickness of 23 mm using a hot-wire knife (being powered by an Oztules PC-PSU conversion... but don't tell him, he may want royalties), then cut it to size and fit it into the lid. Presto. Another 23 mm of insulation on the top. Admittedly, the top of the fridge is the warmest part so insulation will have the least effect here, but every little helps, I suppose...

Now that we have insulated both the rear (radiant barrier) and top, it's time to look at the rest. The door won't be insulated as I don't want the fridge to look as if cousin Bubba and I hacked it. The door will remain as is. To the sides I added sheets of 30 mm styrofoam, cut to size. As I didn't want to glue the insulation to the fridge (for easy cleaning and for warranty issues) I epoxied in a few 12x6 mm neodymium magnets. These hold the insulation to the fridge just fine:

The resulting energy saving of all the extra insulation:

After some measurements it turned out that at a thermostat setting of 4.5 the new energy use is 250 Wh/day, which used to be 340 Wh/day in the unmodified situation. So it turns out we're saving about 90 Wh/day, or 26%. Not too bad! That's another 33 kWh/yr extra shaved off, or about 7 E/yr at today's energy rates. Considering that it took about 2 E worth of styrofoam and a few leftover magnets... not too bad results, me thinks. It means break-even has been lowered to 13 months. Now, these modifications took me a few hours to make and not more than 3 E in materials. But if done by the manufacturer it would take only seconds to install and mere cents in material, but reduce energy usage by another 26%. Amazing that this isn't done at the factory. Peter. 'a penny saved is a penny earned' (more images can be found here: http://picasaweb.google.com/motorconversion/RefrigeratorInsu lation#) |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Hi Peter, I'm not sure if you've see this before but I reckon its the cheapest way to cool for fridges. Cheers Bryan

2008-09-06_191910_chest_fridge.rar |

||||

Gill Senior Member Joined: 11/11/2006 Location: AustraliaPosts: 669 |

Peter, A very interesting read. I've just had my old gas fridge fail, so it's over to the backup 12 Volt chest fridge freezer. Basically it's a small fridge lain on it's back with legs and castors added. A 12 Volt Danfos compressor is fitted to the engine bay with fancy tailored evaporator pipework in the box. In spite the 'Solar' name and 12 Volt compressor it is still a fridge as far as insulation goes and not very thick either considering it could run as a freezer too. I had thought of adding extra insulation but then thought the manufacturer didn't so it can't help much. But with your results that job is now back on the job list. Just when I thought I could put the feet up. was working fine... til the smoke got out. Cheers Gill _Cairns, FNQ |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

I added an inch of polystyrene to all accessable sides on my Engel camping fridge, back in the 70's. This reduced the power consumption to 50%. The reason the manufacturers don't bother is they don't pay for the power a unit consumes. If we all only brought the highest efficiency devices, then we could exert a demand for them. As long as the purchase price steers what we buy, then we get what we pay for. Gordon. become more energy aware |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Bryan, thanks for the file but was already familiar with the Mt. Best freezer-to-fridge conversion. In fact, before scrapping it I took out the electro-mechanical thermostat of the old Bauknecht fridge exactly for possible future duty in such an application. Sorry mate, wasn't my intention to put more work on your platter...  Manufacturers basically produce what sells, i.e. what most consumers desire: a fridge/freezer that is as small as possible (outside dimensions) yet has as much volume as possible (maximum inside dimensions). Guess insulation suffers as a result. BTW, shopping for that fridge was an eye-opener. If I hadn't seen with my own eyes I wouldn't have believed they sold fridges with inbuilt TVs.... Manufacturers basically produce what sells, i.e. what most consumers desire: a fridge/freezer that is as small as possible (outside dimensions) yet has as much volume as possible (maximum inside dimensions). Guess insulation suffers as a result. BTW, shopping for that fridge was an eye-opener. If I hadn't seen with my own eyes I wouldn't have believed they sold fridges with inbuilt TVs....

Gordon, I fully agree. The consumers get the products they desire, as the manufacturers will only produce products that sell. At the moment most consumers just don't care about energy use; and the energy-class ratings (B, A, A+, A++) helps only to muddy the waters (why do they feel the need to introduce vague, ambiguous 'classes', where a simple kWh/yr rating says it all ? One figure expressed in kWh/yr is all it takes. If people are getting confused by this 'technical jargon', maybe they should translate it simply into 'this fridge uses 123 Euro per year worth of electricity'...?) But it's my strong conviction that with rising electricity cost energy efficiency will become more of an issue in the decision making process. Trivia: this new fridge uses 1/9th (11%) of what the old fridge used. The saving is 750 kWh/yr, or 21% of the electricity bill. Now, I did seriously consider buying an A+ class refrigerator, one that is more energy efficient than mine originally was. However, that'd have cost 65E more. I figured I could save the money for a new freezer (highest item on the priority list right now) and simply add a little extra insulation to the fridge to upgrade it to A+ class. Even turns out it now nearly attains A++ class at 90 kWh/yr. This fridge will pay for itself in slightly over a year, the freezer will take about 3 years to break even (at current electricity rates). But with a new freezer the total reduction of the electricity usage would be 48%.... Saved just by replacing the fridge, freezer and PC (from full-tower to notebook). Now, if I can get rid of that electric water heater too... IPSWH?... then electricity consumption might be low enough to start considering going off-grid.  I figure that I could reduce electricity useage down to 1 kWh/day with some effort. Fridge, freezer, PC, some lights, radio, washing machine, HAM gear, occasionally using the microwave. Yes, I think 1 kWh/day should be attainable without quality of life suffering... I figure that I could reduce electricity useage down to 1 kWh/day with some effort. Fridge, freezer, PC, some lights, radio, washing machine, HAM gear, occasionally using the microwave. Yes, I think 1 kWh/day should be attainable without quality of life suffering... |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi dinges, you would be doing exceptionally well to maintain lifestyle on 1kWhr/day. I monitor most appliance usage and my home uses an average approx of 1kWhr per person per day. The water heating is a seasonal problem as we have a solar electric system. We have off peak electric rates for solar shortfalls. The biggest daily culprit for us now is the TV. The electric oven uses a lot, but it is cheaper than eating out. We don't use electricity for heating and we don't need air con. BTW our 25 year old fridge uses 1kWhr per day. We don't run a freezer as the running cost was more than the money we saved by buying food in bulk. The 4star rated freezer still consumed 610kWhr/year. We only use it when we defrost the fridge now. We export a lot of power now, so this offsets the peaks. Good luck, but don't go without too much. Gordon. become more energy aware |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Dinges...................when I get back to the island, I will be looking for the royalty checks.......  yippeee yippeee

Good homework there Dinges, like Gill, it looks like some modifications are in order.... curses. ........oztules Village idiot...or... just another hack out of his depth |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

If you don't find it it means you haven't looked enough... Had another brainwave today as I was cleaning up the mess I call 'workbench'. Harddrive magnets. Should have used those worthless, no good magnets to epoxy into the styrofoam sheets instead of those left over, but nice, 12x6mm round neos. HDD magnets are useless for much else but perfect for this application, even if you damage the plating when removing them: they will be covered in epoxy anyway. |

||||

Bryan1 Guru Joined: 22/02/2006 Location: AustraliaPosts: 1344 |

Ok Oz time to spill da beans on this PC power supply conversion. I did have a look on feildlines without any luck and with me finally going the right way with my shed wiring a pc power supply conversion is right up my alley for a project or 3

Cheers Bryan  |

||||

oztules Guru Joined: 26/07/2007 Location: AustraliaPosts: 1686 |

Hi Bryan, Dinges did an excellent how-to on fieldlines here:Dinges showing his stuff It should give you some idea of the conversion process... (and another whole lot of waffle besides). He has also used them for his beautiful looking spot welder here :Dinges spot welder If you start a thread of your attempts as well, we can guide you through it if you have any trouble, and perhaps others looking at it, may find better ways to do it too. Go for it Bryan, you won't look at psu's at the tip the same way ever again.... ask Dinges. .......oztules Village idiot...or... just another hack out of his depth |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Bryan, Must definitely have a look at this thread (esp. response 31 and further), where Oztules originally explained the modifications a few years ago: http://www.fieldlines.com/story/2006/4/24/92132/1267 One thing I'd certainly add though is a 22/47/100n capacitor over the wiper of the voltage-control potmeter. This helped one PSU from tripping to a halt, and I strongly suspect it's the reason why another PC PSU I was building for Ron blew up (actually, it was all finished up and encased; as I quickly needed a power supply for some experiment I grabbed that PSU, only to have it blow up as I adjusted the voltage potmeter) As I said somewhere in the thread, Oztules deserves an innovation award for turning worthless, useless PC junk into valuable laboratory supplies. One of them even kept a friend's Jung grinding machine working for 3-4 months as we were waiting for a new transformer to arrive from Switzerland (darn; forgot to send Oztules a royalty check for that one). Once you have such a power supply you will wonder how you ever managed to live without it...  . .

This is *incomparable* to the web-nonsense where you see people adding power posts to an otherwise unmodified PC PSU and claiming that it's now a laboratory supply... But Oztules' mods *will* turn it into one. |

||||

| domwild Guru Joined: 16/12/2005 Location: AustraliaPosts: 873 |

Peter, Interesting article and thanks for it. As you know some members simply buy a freezer and add a different thermostat setup. But this is certainly a dearer option. The gap on top must be used to fool customers into believing they are getting a larger fridge. Taxation as a means of achieving prosperity is like a man standing inside a bucket trying to lift himself up. Winston Churchill |

||||

| robbo Regular Member Joined: 25/03/2007 Location: AustraliaPosts: 71 |

Hi there Guys, Not to rain on your parade, but I've seen many fridges that get really hot on the sides, when they are hard at work. Feel the sides of your fridge for heat mostly in the Summer, or on a hot day. javascript: ('  ') ')

Insulating on the sides wouldn't be recommended by the manufacturers, as they recommend a minimum 5 cm space on each side of the fridge, to allow air to flow around. If we are placing insulation on the sides, this will only hold the heat in. I absolutely agree that the rear and underside should be thermally shielded from the motor and cooling ribs. It would be nice to have a Kilowatt meter to use to do such the same experiment as we use two fridges and one Freezer in my house. We recently turned off the freezer, as the two fridges had their own, and it was more mismanagement of old food, then not enough space. (I had a piece of weeding cake in the freezer from more than 10 years ago.) javascript: ('  ') ')"the Earth was not given to us, by our fathers, rather, it is lent to us by our children". |

||||

| petanque don Senior Member Joined: 02/08/2006 Location: AustraliaPosts: 212 |

If it is an old fridge often the compressor wears and so is not as efficient. If you really wish to save energy it may be worth investigating a new fridge. If the inconvenience of a broken fridge is worth more or less than the savings from delaying the purchase would be a personal thing. While I donít know the taxation system where you live but often a penny saved is equal to a penny earned + tax. |

||||

| Dinges Senior Member Joined: 04/01/2008 Location: AlbaniaPosts: 510 |

Robbo, notice that this particular fridge has the condensor coils on the outside, not in the walls. I must say I've never seen one where the condensor coils are -not- mounted on the rear-outside, but I understand that it's pretty common in the US to have the condensor coils in the sidewalls. Why ? Beats me. Thermodynamically it's a stupid thing to do. But you're right, if the manufacturer had mounted the condensor coil in a sidewall it would be very unwise to add extra insulation over it. The manufacturer for this fridge only mentions a minimum required space for the bottom and rear. I'm obeying those requirements. I understand the air flows under the bottom, upwards the condensor coil and outwards of the ventilation roster at the top rear. And on the right of the fridge there is about 15 cm of free space as well. Now, the proof of the pudding is in the eating: if my added insulation would hinder ventilation/cooling of the condensor, energy use of the fridge should actually increase. Which it doesn't - energy consumption has gone down. Don, it is a new fridge. Ok, the next part of the energy-reduction quest... Just brought home a new freezer, energy class A+.

Manufacturer claims an energy use of 223 kWh/yr, or 610 Wh/day. The current freezer used 2.3 kWh/day which, during the past few months, I managed to reduce to 1.7 kWh/day. So the new freezer should save at least another 1.1 kWh/day on the energy bill. With some extra insulation hopefully a bit more. I'll report back here on the results of the freezer insulation project, after I've gathered some good data on the energy use in the as-is condition. |

||||

| vawtman Senior Member Joined: 14/09/2006 Location: United StatesPosts: 146 |

Hi Peter What if you wired in a muffin fan to the compressor circuit so that when it's running the fan would help dissapate the heat from the coils? Worth an experiment er no. |

||||

| Don B Senior Member Joined: 27/09/2008 Location: AustraliaPosts: 190 |

Hi Peter, From my days of making refrigerators for boats, there are a few points worth noting. It is stating the obvious to say that, apart from removing the heat from the fridge contents, the other main task of the refrigerator unit is removing the heat that has got in from the outside through the insulation. Most boat fridges are insulated with rigid polyurethane foam (usually green), and, for good efficiency, the rule of thumb used to be to use 100mm thickness for fridges, and 150mm for freezers. I had a quick look for the relative R (heat transfer) factors of polystyrene and polyurethane without success, but I believe that polyurethane is a superior insulator to polystyrene for a given thickness. One of the important things with fridge insulation is to stop atmospheric moisture condensing within the insulation and spoiling its effectiveness. One way of doing this is to wrap the outside of the foam in plastic sheet, and seal it with duct tape. Moisture absorbsion over time can be a particular problem with polyurethane foam. Condensation may be less of a problem with polystyrene, which, I think, is a closed cell foam, but you will find condensation under the external polystyrene sheets that will, in time rust the fridge cabinet if it is steel. This condensation will also drip out over time, which may be another nuisance. The other thing that will improve fridge efficiency is to help the unit get rid of the heat at its condensing coils. This can be as simple as improving the ventilation by somehow bringing cool air past. On some boats, the condensing coils are run through the fresh water tanks, or even outside into the sea water to obtain maximum cooling. Building your own DC fridge or freezer is really not all that hard. You make a well insulated cabinet with maybe a fibreglass interior liner, and preferably with a top opening door. You purchase, or make up, the evaporator tubing arrangement to fit inside to do the cooling, and bring the tubes to the outside. Don't forget to also build in a drain at the low point (with a u bend trap to keep the cold in). The DC fridge units (condensing units) are available from most ship chandlers, and no doubt other sources. Danfoss is one popular and long established brand. The connection and gassing of the unit is best done by a fridge mechanic, and, after that, all that you have to do is supply the amp-hours. Note also that there is no rule that says that the DC unit has to be mounted on, or under, the cabinet. As these units necessarily produce heat, it is actually better to locate them clear of the cabinet, preferably somewhere cool. If the cabinet is fixed (ie built in) then the interconnecting tubing to the condensing unit can also be fixed into place. The DC units can work as either a fridge or freezer. Apart from the extra insulation thickness for a freezer, the only difference is in the range of the thermostat. The unit manufacturers can give some guidelines here. While building your own fridge or freezer entails more work than buying one, the extra insulation thickness that you can build into your own cabinet will guarantee that you get a more efficient fridge for a given internal volume than a "thin" commercial one. You also get a DC powered fridge, that is more readily suited to a renewable energy system. A final caution though is that anything that cools or heats uses a lot of energy, and you need to look at your energy balance carefully if you are contemplating a DC fridge in an off grid situation. Regards Don B Don B |

||||

| GWatPE Senior Member Joined: 01/09/2006 Location: AustraliaPosts: 2127 |

Hi all, building your own fridge is complicated now by new regulations controlling refrigerant gases. Gordon. become more energy aware |

||||

AMUN-RA Senior Member Joined: 10/03/2007 Location: AustraliaPosts: 144 |

http://www.ozefridge.com.au/default.htm look here then build your own comes pregassed and is as easy as to get going look I have one and they are great multi voltage 12/24 110/240 just plug them in can be air or water cooled user selects temperature withe the push of a few buttons. Peter is a great help with any set up problems this guy knows his stuff when it comes to fridges Mick  Every day the sun shines & gravity sucks= free energy. |

||||

| greendreamin Newbie Joined: 02/02/2008 Location: AustraliaPosts: 20 |

yeah i have been looking in to this too waeco make these plug in units too simply mount th evap in your enclosure and you usually get reasonably long hoses so you could have your enclosure inside and mount the compressor and condenser out side where it will work heaps better some even have water cooled condensers which improve the efficency heaps, or you can get one of these oneshttp://www.ozefridge.com.au/default.htm its eutetic a kind of thermal storage so you could set it to come on when your batteries are on charge IE:pl40 remote terminals. and turn off at nite and use the stored energy, saving on battery storage capasity idesl for a off grid application these units look like they have quick connect couplings so they dont need to be gassed up you simply connect the hoses and your ready to go Stu

Sorry just red the post above mine and it looks like micks already on to it |

||||

| Page 1 of 2 |

|||||