|

|

Forum Index : Other Stuff : tinkers home made bandsaw

| Author | Message | ||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

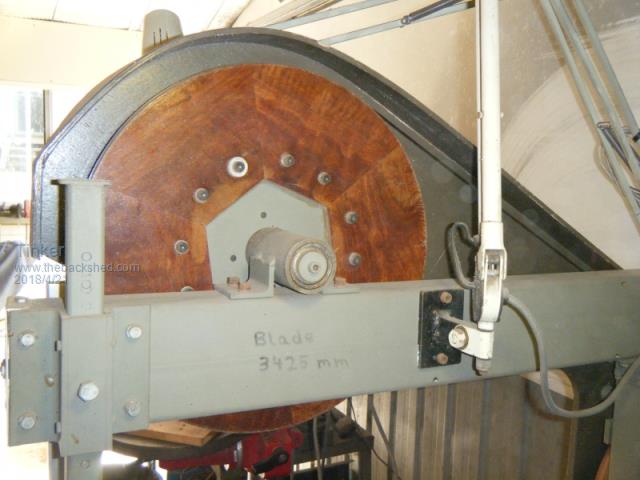

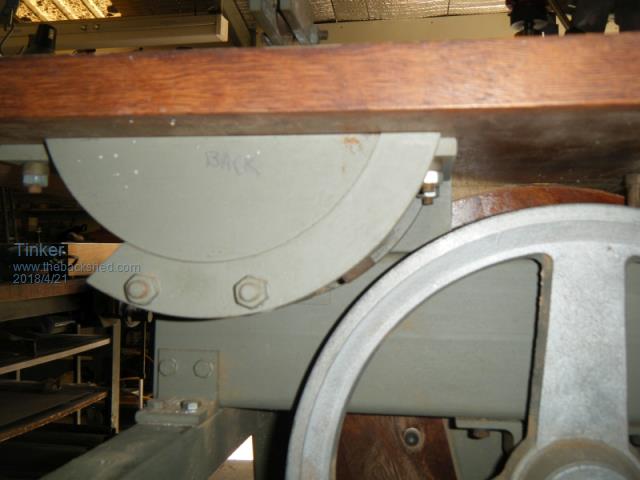

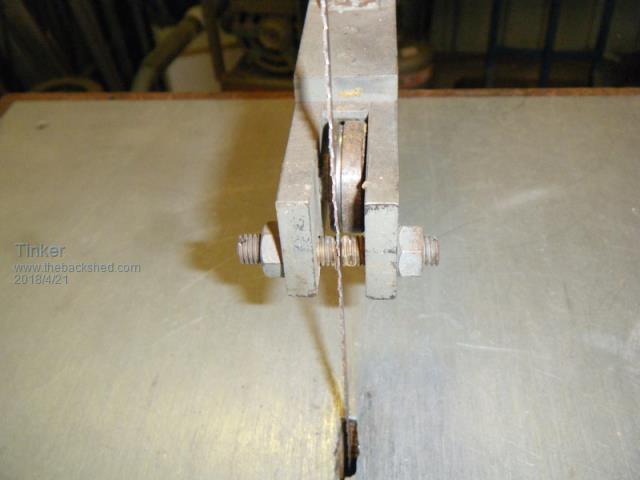

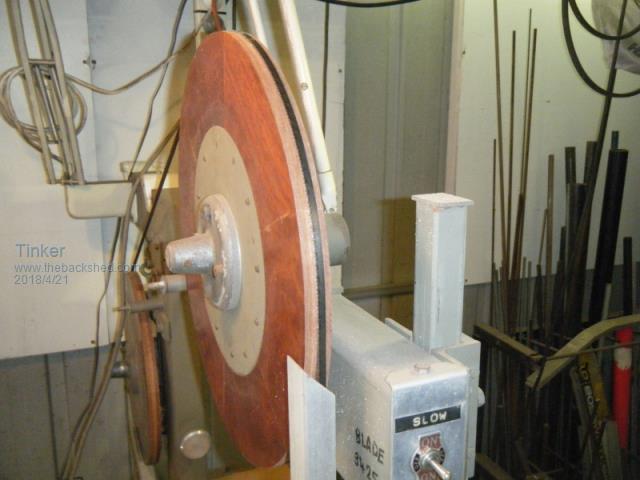

After seeing Gizmo's bandsaw picture gallery and reading comments that this DYI bandsaw building interests others, here is my version that withstood the test of time, having been built in the mid 80's. The top saw guide is a two stage telescopic affair to allow material up to 300mm thick being cut. Throat opening is 600mm, this would require gigantic wheels for a two wheeler...  Segmented hardwood wheels & bearing arrangement.  Blade tension & tracking setting.  Idler pulley for dual belt speed. The motor is also two speed.  Table tilting, a wee bit more rigid than a hinge...  Top sawblade guide. I used second hand bearings which had a nice groove in them. This is the second bearing, the first lasted over ten years.  Bottom saw blade guide and rear view of tilting mechanism.  Hinged motor for belt tensioning - works very well.  Table fully tilted to 45 degrees.  The wheels are rounded at the blade running surface, a la flat belt pulleys. This tracks very well with my tracking adjusted correctly.  The eagle eyed might have noticed that my bandsaw frame is bolted together, not welded. Two reasons for that: 1. there is no frame distortion from welding by this hobbyist welder  . .2. the rather large frame can be dismantled for transport. Frame members are 100x50x3mm RHS steel. Klaus |

||||

Revlac Guru Joined: 31/12/2016 Location: AustraliaPosts: 1024 |

Nice work there Tinker  There is some interesting ideas as well, definitely a way to get a big throat opening.  What HP is it? Cheers Aaron Off The Grid |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Thanks, the motor is from an old washing machine, I think 1/2Hp, have to look at the label to be exact. Two speed winding is very handy. Klaus |

||||

| plover Guru Joined: 18/04/2013 Location: AustraliaPosts: 302 |

Another delightful project to look at and dream about. Congratulations. Since I am not coming from a mechanical engineering background it took me a little while to figure out the tilting mechanism. Can't say I have the complete detail but I can imagine how it could be looking. Where did you get the idea to the saw from? The internet was not exactly widespread when it saw the light of day? |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Thank you, I will take the table top off tomorrow and take a better pic of the tilt mechanism. Its basically segments of thick wall tubing, sliding on an arc. A simple hinge will be very wobbly for that and difficult to lock up rigid. This mechanism is a copy from a commercial bandsaw (Durden?). I was using one of these at work and pinched the good features of it, like the tilting table, the wheel/ blade alignment & blade tensioning system. Did not like that axial bearing blade guide idea that saw had, since I had to replace those bearings far too often, hence my radial bearing arrangement. Also, that machine had only 2 wheels and the resulting cutting width limit was not appreciated, hence the 3 wheel idea. 3 wheels have the added advantage of the lower (driving wheel) *and* the upper wheel being on fixed bearing blocks and very rigid, no fancy sliding adjustment required there. The third wheel has all the adjustment, its the best place, IMO, for that. You are right there was no internet back then, that resource only surfaced in the mid nineties at my workplace & 10 years later at home  . .Klaus |

||||

| Gizmo Admin Group Joined: 05/06/2004 Location: AustraliaPosts: 5078 |

Trust you to turn this into a pissing contest. Nah, hinges work well if set up correctly. I used 2 large hinges in line and replaced the pins with a single long over sized pin. The result is a long hinge with no "wobbly". The bed angle is adjusted and fixed at the inner edge of the table just behind the main upright, easy access and rigid, as the bed is secured to the frame. Hinges are easy to implement, but the disadvantage is the hole in the bed where the band comes through is larger on top. Glenn The best time to plant a tree was twenty years ago, the second best time is right now. JAQ |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

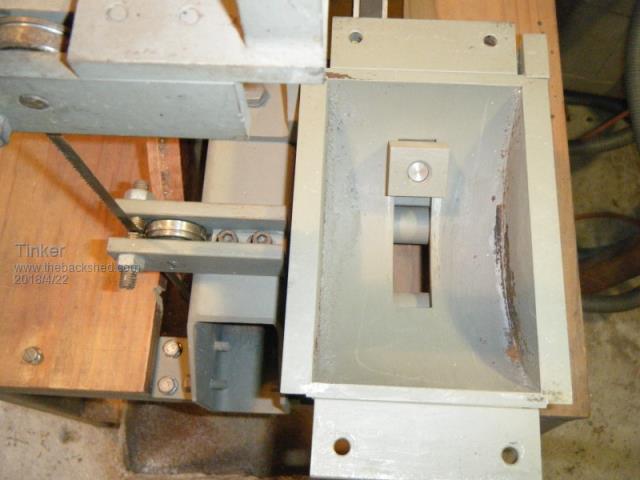

Nah, no contest intended, just showing an alternative method. There was no mention in your post that there were two hinges. Yes for table tilting, the blade 'hole' in the table needs to be larger but mine is beveled on the underside and just a narrow slot on top. Probably only works with a mechanism as shown in the following pics. With a larger blade opening, if there are small bits trimmed of an edge, the offcut can drop into the lower blade guide and jam things up. Following are some pics of my alternative table tilt mechanism.    Back in the days when I built that saw my workshop did not have any fancy machinery to make parts for it. I had access to a Hercus lathe, a metal cutting band saw, bench drill press and a gap bed wood turning lathe (for the wheels) at work. Klaus |

||||