|

|

Forum Index : Solar : My first LFP battery install

| Page 1 of 3 |

|||||

| Author | Message | ||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

After talking about it and thinking about it for close to 4 years I have finally got my hands on a LiFePo4 to install. Ive got a feeling it wont be the last! Its a 24volt 400Ah bank. This photo is just before I fired up the banding tool and clamped the cells together. The cell voltages averaged 3.2908 volts out of the box with the highest at 3.2933V and the lowest 3.2889V. I couldn't make a decision about how to charge and balance them before I get to the installation stage. I thought they were close enough that I didn't need to wire them parallel for an initial balance before I started. Originally I was going to charge each cell individually with a Revolectrix Cellpro Powerlab 8(V2). In the end I decided against it as I was keen to see what the charge curve would look like with a standard charger. I temporarily assembled the pack and bulk charged it to 27.6 volts (roughly 3.45 volts per cell) making sure that all the cells were under 3.6 volts and the shunt modules had not triggered. I had a 12 volt spotlight standing by that I could use to drain some power from a cell if the voltage got too high and it started to shunt power but happily I didn't need to use it. Then I split the bank in half and charged it with 2 smaller 12 volt chargers that would cut out at 14.4 volts and not overload any of the 2 amp cell shunts in the process. Need to be cautious because I have not wired the Battery Control Unit in at this stage so there is no protection for a over volt cell other than the 2 amp shunt. With each half of the pack getting close to 14.4 volts, four of the cell modules triggered at 3.6 volts and started to balance those cells. This one bypassed the most at 0.6 amps for about 10 minutes. the others were less than 0.2 amps for less than 5 minutes. A bit of an anticlimax in the end, I was expecting to have to work a bit harder than that. At the end of all of this the pack has taken a total of 281 Amps, that's about 100amps more than I expected, as I was advised that they come 50% to 60% charged when you get them. So now it is charged, I'm ready to clean and prep everything for the final install. I'm confused, no wait... maybe I'm not... |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Top stuff, will be following this with much interest. We come from the land downunder. Vic |

||||

| davef Guru Joined: 14/05/2006 Location: New ZealandPosts: 499 |

Likewise. I will be due a new battery system in a year or so. Thanks, Dave |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Nice looking set of Batteries , are these for your own set up or is it for a customer and what Amp/hr cost did you get them for? Lithium still seems to be very expensive for the ongoing worry of warranty clouded with correct BMS cell balance . The big players out there in the charge controls are yet to still come on board with set and forget Lithium Charge Algorithms. There will be some great advantages to be had with these batteries in hybrid grid and off grid systems in future years but compared to lead acid lithium is still in its infantsy. To see what happens with pricing when the large companies take control of the market with sales set to skyrocket with the emerging EV car market, will it be interesting or disappointing. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

These are for a customer, solar only upgrade to an existing system. Warranty and some clear guidelines on charge/discharge parameters are two of the main reasons we have chosen these particular cells to dip the toe in the water. CALB offer 18 months 100% warranty plus 18 months 50% warranty. In this situation that will be 1000 cycles anywhere from 50% to 85% discharge. We think that is very reasonable and worth a calculated risk. In fact I think they are probably overspec for an off-grid install. The big unknown, as always, is the projected life of these things and the total Kw in that time period. My gut feeling is the electronic hardware will fail before the battery bank runs out of puff, so provided the BMS can still isolate the battery from the rest of the system and it is regularly checked to see that it is functioning as at should be, I think we will be fine. I am not going to say anything about the upfront cost, there are plenty of suppliers that will be happy to quote people a price if they are genuinely interested and there are new options available every few months. Likewise I wont be saying much about the detailed inner workings of the BMS, its not my intellectual property. I will however do my best to detail and explain the set points and limits I need to get a solar controller working with this bank and how it differs from working with lead acid cells. This has been the hardest thing for me to get my head around, simply because there has been so much misinformation and rubbish spoken about LFP's and confusion with other lithium cells in the recent past. I'm confused, no wait... maybe I'm not... |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

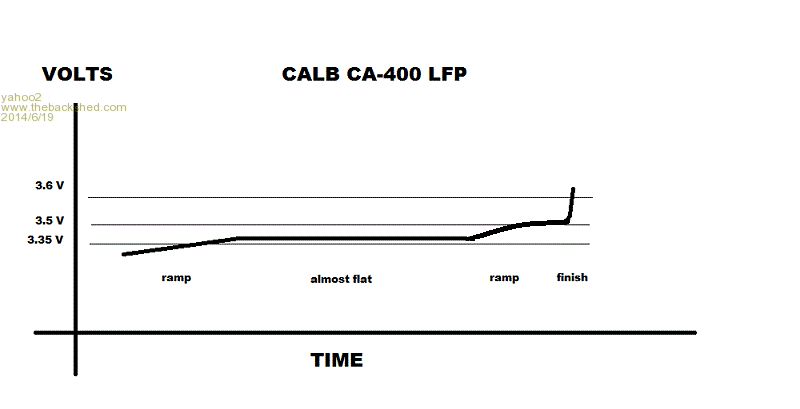

One of the things the more observant of you may have already noticed (if you dusted of a calculator) is the higher voltage we are dealing with here. I will convert the volts to 4 cells so I can compare it to 6 cells 12 volt of wet lead acid (WLA). (cell volts in brackets) nominal volts for LFP (3.2V) 12.8 volt state of charge delivered was 30% @ 3.29 volts/cell for the LFP's 30% SOC CALB LFP(3.29) 13.16 volts WLA____(1.96) 11.75 volts One thing I noticed while charging is the curve has two distinct ramps and two sections that are almost flat. At one point one of my multimeters was not capable of measuring the cell voltage rise, the other one was ticking over at one ten thousandths of a volt every two and a half minutes, that is almost billiard table flat. The voltage rise is very rapid at the finish, even with the tiny chargers hooked up it was going up at one mV every 2 seconds. This looks to be a distinctive characteristic of charging the CALB cells at less than 25% of their capacity.

I'm confused, no wait... maybe I'm not... |

||||

| norcold Guru Joined: 06/02/2011 Location: AustraliaPosts: 670 |

Dead on plenty of misinfo out there. I know from my experience with LiPo, have not had a failure in the 4 or so years I`ve used them in RC Gliders, they are brilliant. Constantly taking down to 20% DOD, balanced recharge each time, they have been flogged. They have totally replaced NiCd and NiMh, lighter, higher discharge rate and more reliable. If LiFePo4 can duplicate that in solar storage, Pb acid will go. RC chargers whilst too small for the larger capacity required(400 watt), seem to have balanced charging down to pat and as a bonus can charge Pb, NiCd, NiMh, and the Li`s. We come from the land downunder. Vic |

||||

Downwind Guru Joined: 09/09/2009 Location: AustraliaPosts: 2333 |

Recording a pack voltage only tells a small part of the overall view, i would say almost useless information, To log and plot each cell will be a tell all of what the pack is doing. You have some dinky device on each cell to control the max voltage, Is it actuactually doing what you expect it to do, or is it doing what it wants to do. Untill you log each cell then its pointless in posting pack voltage curves, they tell nothing, as the important part is when the cells reach full charge (in the mV range)and how the cell controllers work at that point. Lets look at a log plot of the equalizer off for a period in the day. As you can see how far each cell (coloured line) becomes seperated from each other. Then we look at a day with the equalizers on and how each cell follows the other. As you can see there is a big difference to each cell, and its up in the Mv range and not down in the general bulk charge range that matters. Pete Sometimes it just works |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Thanks, The shape of the bulk charge curve is just my observation of what happened, I recall someone telling me a few years ago it was some sort of gassing and re-absorption that caused it. What it does show, is that for a large part of the batteries capacity measuring the voltage would give no reliable indication of the state of charge. Any sort of capacity meter will have to be counting amps (or coulombs). I took a guess at how much charge these would take, based on some old thundersky data I had and the voltage, I was out by 100 amps. I started to think some ninjas or bunyips had been sneaking in and switching my charger off while I wasn't there  . .

The manufacturer says these cells are regarded as fully charged at 3.50 volts, so yes Pete, it wasn't till I got above this point (plus some mV for charging resistance)that I started to see any useful spread of voltage between the cells. Even then, with new cells it was tiny. I'm confused, no wait... maybe I'm not... |

||||

| VK4AYQ Guru Joined: 02/12/2009 Location: AustraliaPosts: 2539 |

Hi Yahoo2 Very interesting work and the charge voltage plotting, I have a small charger that is designed for model use and on checking out the way it works I have come to the conclusion that it charges the bulk charge across all cell the same until it gets them nearly full charged then goes into a PWM mode and tops up to max voltage on each individual cell, by measuring the voltage of the cell in the off section of the PWM cycle, as the voltage comes up to fully charged it cuts the PWM back on each cell reducing charge until it reaches max voltage and it seems to monitor that voltage until all cells are the same, then it sits measuring voltage on each cell and if it sags down a bit it will give that cell a bit more charge. Quite a intelligent thing for $54 at the model shop. I have on occasion forgot to disconnect it but it just goes on working without killing the battery. There is hope for us yet. All the best Bob Foolin Around |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

I went back and had a read of Tinkers topic on ultracaps and LFP's after Phill mentioned it in Dom's topic this morning. a new way to balance lithium ion battery Still a good read after almost 2 years.   Has it been that long? Has it been that long?

I am quite relieved I didn't write anything completely embarrassing at the time but I can see that my attitude to balancing and charging LFP batteries has changed a bit since them. I am not as uptight about keeping them completely balanced and fully charged. Given that I'm only dealing with one series of 8 cells and max charge rate of 0.3C and discharge of 0.6C. I asked myself the question, "How long could it potentially run, without balancing and still not trigger the individual cell overvoltage or undervoltage set points on the battery management system? Back then I was thinking in terms of perhaps a few weeks. Now I think that a bank of matched cells with good electrical connections that is lightly used could possibly take up to one to two years to get that far out of sync. Would there be any damage as a result? No, I dont think so. So what about full charge? is that critical? No, as long as the cells are spending most of the time above 30% state of charge they could go for months without being "topped up" with no ill effects. I am not saying I would actually do this (charging lead acid style is just too ingrained in my psyche)but it does change how I would use a generator and charger in winter. After a few cloudy days you might look at the meter and see that there is not enough juice to make it till the sun is up tomorrow so you might pump 50-100 amps in to tide thing over till the morning. No more worry over calculating time at absorption levels to avoid sulphation. If the battery is keeping up, just let it do its thing. I'm confused, no wait... maybe I'm not... |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

What I have heard from a fairly reliable source is that with Lithium Batts and off grid applications , you can easily get by with out fancy balancers and are not really required if you keep away from the upper charge limit as to the lower limit . It is the EV people that are always needing to get max charge as well as the massive current draw and Charge rate imposed and required for that application , it is stated and with lithium it does not damage the batts to only charge to 90 ~ 95%. and run between 30% and 80% where with Pb Acid it is sudden death . I would think just the same as you have, and monitor the cell voltage and regular intervals would be sufficient and manual balance when required , when charge and current draw rates are well below the maximum allowable limits. Its a suck it and see as there is not much info out there about these batts , the yachties and Grey nomads seem to be the ones using them from the last time I was thinking of purchasing some. PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

Thanks for the "good read" comment. You may be interested that this balancing system is still used today though by now it is vastly different from the basic 'hit and miss' way of balancing it once was. It uses a picaxe chip to determine which of the 8 cells has the highest charge potential and the lowest potential. It then connects the supercap across the HI cell to absorb charge and follows by connecting it across LO cell to dump charge. This is done 5 times after which it again seeks the Hi/Lo cell and repeats the process. Works very well for my setup. The cells balance to within <5mV of each other during bulk charging. There is no balancing when the charging current drops below 1A (after daylight) but I do have a separate Lo cell voltage disconnect as well as Hi cell voltage disconnect for the Lipo section of my battery bank. There is enough solar power available to fully charge the bank by midday on sunny days and it is then that the equalising part becomes very important. Solar charge is controlled by a 60A MPPT charge controller which at its equalising stage will place 3.65V across each cell *if* they are all equally charged. They go very quickly to much larger cell voltage differences if no equalising were done. Large enough to approach the manufacturers max cell voltage (4.0V) for the Hi cell. But my Hi cell disconnect (set to 3.7V) prevents that happening. Total bank (200Ah Lipo & 600Ah LA) charging current near the end of the equalising stage is around 2A. Klaus |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

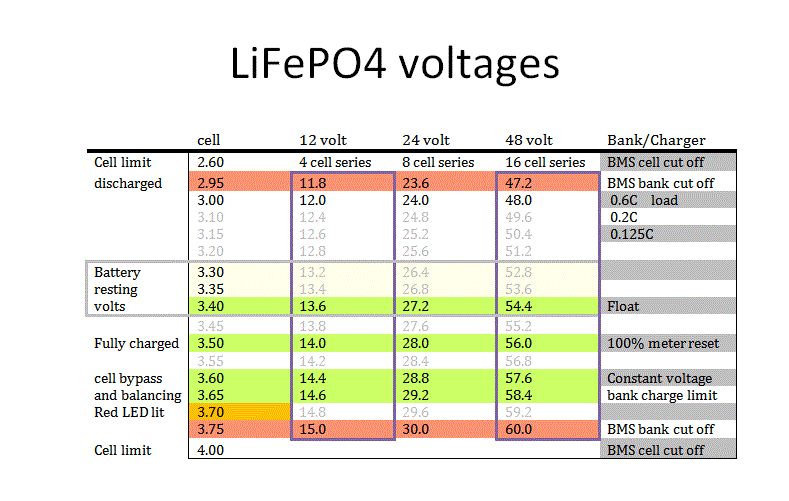

I'm getting tired of recalculating voltages all the time so I have done up a cheat sheet as a quick reference for myself.

I'm confused, no wait... maybe I'm not... |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

I have hit my first snag. All my own fault. I thought I could reuse some parts from the old system because it was a much larger 12 volt setup and would handle the amps of the new 24 volt batteries. After having a close look at the cables and switches, I have realised I will have to fit new stuff, the cable is all smaller and higher resistance than it should be and there is some damage from acid. The other issue that I missed was the thread size of the cell terminals. the 400 AHA cells take a M14 stud, most suppliers jump from M12 to M16 in brass and stainless steel fittings. Lug terminals with a 14.5mm hole are not "off the shelf" nor is 14mm threaded rod. I need to make two longer battery terminals and I was going to use brass allthread. I will have a scout around my shed, I have some s/s studs that are surplus submarine parts, there might be some M14's in that lot I can use. The terminals are not a big issue, but wiring to handle 250 amps continuous and 400 A for a second or two certainly adds to the cost for what is a relatively small system. Just one of the many downsides from not doing a fresh install from scratch with 48 volts. I'm confused, no wait... maybe I'm not... |

||||

fillm Guru Joined: 10/02/2007 Location: AustraliaPosts: 730 |

Wouldn't the extra parts and labor be at their cost? Oh-No... or was it a fixed quote and no allowance was made for wiring mods and the unexpected.  PhillM ...Oz Wind Engineering..Wind Turbine Kits 500W - 5000W ~ F&P Dual Kits ~ GOE222Blades- Voltage Control Parts ------- Tower kits |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Guess its time for an update. Fitting and commissioning the batteries was quite smooth. Apologies for no photos, my camera battery is pretty toasted and wouldn't drive the flash. 70mm2 battery cables and a 400A switch bolted straight up. I soldered and epoxied all the sensor wires for the management system and cleaned the cell terminals with a new file before coating it with dielectric grease and torquing it all up. I rewired the old 12volt panels in pairs to get 24 volt and fitted an pretty standard (basic) PWM controller. Its going to be expanded with a fresh solar bank and controller before next winter so we are using what I have on hand ATM. The battery setpoints we are currently using are for a sealed lead acid. they charge to 28.3 volts, then have an eq charge to 28.7 every 25 days. Originally I was going to disable the temperature compensation on these units and wire a diode or two in the battery sense wires to trick them into charging to the higher 29.2 volts. I have since decided it is not worth the effort for the 8 months that they will be installed. The batteries will function just fine as they are. The first thing that I noticed when the solar switch was thrown was that the batteries took everything that the panels pumped out even though they were technically full, they charged full blast for about 3 minutes then the PWM cut in and within 20 seconds it was back to the float voltage. There is almost no absorption (constant voltage) phase at all, I presume this is because the internal charging resistance is so much lower. It will be interesting to see how much sooner in the day we get to full charge. I loaded the inverter up to its 30 minute rating and sucked 150Ah from the batteries to check it all out, the battery voltage dropped to 25.6 volts under load then sat at 26.3 after we finished. The thing that has struck me since the installation is how much flexibility there is in charging and discharging, with the relatively modest amperages in a RAPS. About the only thing I can think that could damage them is to drain them till the BMU disconnects, then forget to manually reset things in the morning (so they can recharge) before going away on holidays for a month or two. Pretty much everything else they take in their stride. The only regular maintenance is to cycle the relay contactor and test that the battery management circuit is functioning correctly every couple of months. The only issue I can see is that with the temperature compensation coefficient still working it would be technically possible to get above my 29.2 volt limit if a very cold day coincided with the Day 25 equalisation cycle. I'm confused, no wait... maybe I'm not... |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

There is an easy way to do that automatically. I purchased a high power schottky diode pair with a common cathode and put that in series with the positive lead to the LYP battery bank. Each diode is normally shorted out by the contacts of a latching relay (mine have 80A contacts). The latching relay are operated by the BMS, one opens at over voltage and the other at under voltage. The diodes ensure that if, say, under voltage trips, charge can still flow into the bank but nothing out until the bank voltage has risen sufficiently. Tinker Klaus |

||||

| yahoo2 Guru Joined: 05/04/2011 Location: AustraliaPosts: 1166 |

Well the LFP bank has been cycling for a couple of months now. I am happy to report that the predictions we made at the start have happened, despite the controller settings being lower in voltage than the 28.8 volts (3.6V/cell) needed to begin the shunt bypass. There is no detectable imbalance between the cells, at least not with my old multimeter, after 50-something cycles and no balancing.

I am still amazed at the way they charge. If there is any capacity left to fill, it is just wide open throttle until the last few minutes, even though the absorption phase light has been flashing for an hour. After spending so much time watching lead acid batteries meandering towards full charge, I feel like I will never get used to that. I'm confused, no wait... maybe I'm not... |

||||

| Tinker Guru Joined: 07/11/2007 Location: AustraliaPosts: 1904 |

How old is your multimeter? does it read down to mV differences? On my LFP there was no cell difference (<10mV) during most of the cycle. Only at the top of the equalising period did the cells differ by up to 150mV, strangely the two cells closest to the connection of the charging cable always having the highest potential. I did not realise this until I started logging the individual cell voltages during a 24 hour cycle. I have now added adjustable 4A shunt regulators, they had hot heat sinks on the first equalising cycle after fitting them. After that all heat sinks are always at the same ambient temperature and the logging graph shows all cell equalise to within 10-15mV of each other. Klaus |

||||

| Page 1 of 3 |

|||||